Steel Sand Casting Suppliers A Comprehensive Guide

Steel sand casting is a widely-used manufacturing process that offers numerous advantages, including high strength, versatility, and cost-effectiveness. This technique involves pouring molten steel into a sand mold, allowing it to solidify and take shape. As industries evolve and the demand for quality castings grows, the role of steel sand casting suppliers becomes increasingly critical. This article will explore the importance of these suppliers and what to consider when selecting one.

Why Choose Steel Sand Casting?

Steel sand casting stands out due to its ability to produce complex shapes and various sizes. It is particularly favored for large components in industries such as automotive, aerospace, and construction. The durability and mechanical properties of steel make it suitable for high-stress applications. Compared to other materials, steel castings offer excellent performance and longevity, further justifying their selection in engineering projects.

Identifying Reliable Steel Sand Casting Suppliers

When looking for steel sand casting suppliers, several factors should be assessed

1. Experience and Reputation Suppliers with a solid track record are often more reliable. Research their history, client testimonials, and previous projects. A reputable supplier will have a portfolio showcasing their capabilities and customer satisfaction.

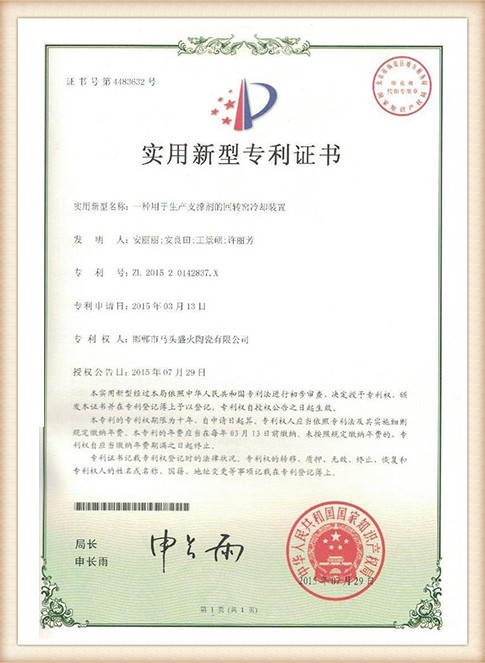

2. Quality Control Quality is paramount in casting processes. Ensure that the supplier adheres to rigorous quality control standards and possesses relevant certifications. ISO 9001, for instance, indicates that the supplier meets international quality management standards.

steel sand casting suppliers

3. Production Capacity Evaluate the supplier's ability to meet your production requirements. This includes lead times, production speed, and scalability. A supplier with advanced machinery and a skilled workforce can often fulfill larger orders and handle complex projects more efficiently.

4. Material Options Different projects require different materials. Ensure the supplier offers a range of steel grades and can accommodate specific alloy requirements. This flexibility can be crucial for achieving the desired mechanical properties in your castings.

5. Technical Support and Collaboration Choose suppliers willing to engage in collaborative discussions about design and manufacturing processes. Their technical expertise can help improve your product's design, reducing costs and enhancing performance.

6. Cost Competitiveness While cost shouldn’t be the sole determinant of your choice, it’s vital to get quotes from multiple suppliers. Always consider the balance between price and quality, as the cheapest option may lead to compromised safety or structural integrity.

Emerging Trends in Steel Sand Casting

As technology advances, so does the steel sand casting industry. Suppliers are increasingly integrating automated systems and advanced software for mold design and production. These innovations lead to improved accuracy, reduced waste, and shorter lead times. Furthermore, environmental considerations are prompting suppliers to adopt more sustainable practices, such as recycling sand and minimizing energy consumption during manufacturing.

Conclusion

Selecting a reliable steel sand casting supplier is crucial for achieving high-quality castings that meet your project requirements. By considering factors such as experience, quality control, production capacity, and technical support, you can find a partner that aligns with your needs. As the industry evolves, staying informed about emerging trends can help you leverage the latest advancements in steel sand casting, further enhancing the efficiency and quality of your production processes. Engaging with the right supplier ensures not only the longevity of your components but also the overall success of your projects in competitive markets.

Post time:Hyd . 15, 2024 18:04

Next:Techniques for Achieving a Smooth Finish on Clear Resin Through Sanding