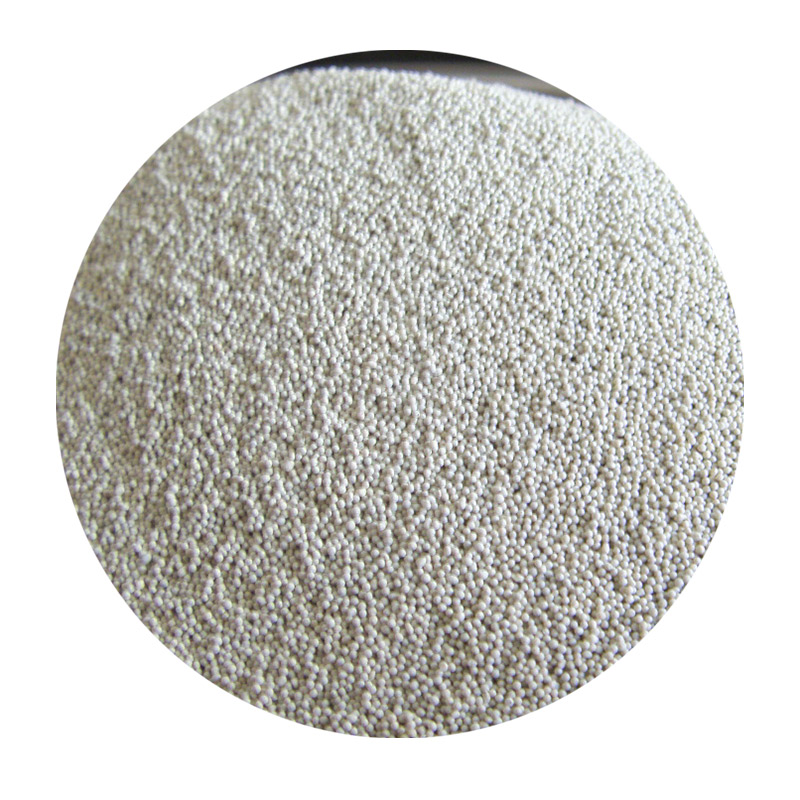

From an expert perspective, it’s vital to consider the binders and additives used alongside sand. Bentonite clay is the most commonly used binder, providing the necessary binding forces between particles, while additional materials like coal dust can enhance surface finish and reduce casting defects. Mastery in selecting the appropriate combination is paramount for optimizing the casting process and minimizing imperfections such as sand inclusions or gas porosity. The integrity of the sand, therefore, directly correlates with the casting quality. Frequent testing for sand properties—such as compactability, moisture content, and permeability—can guide adjustments in the casting process. Moreover, being attuned to the latest advancements and modifications within the industry can also confer a significant competitive advantage. The ongoing evolution in sand technology strives to enhance reusability and reduce environmental impact, aligning with contemporary demands for sustainable practices. Authoritativeness in sand selection and usage also demands a deep understanding of post-casting operations. After pouring and cooling, an effective method for reclaiming sand, ideally through mechanical or thermal reclamation processes, should be in place to ensure that the sand’s properties remain intact for subsequent use. In conclusion, navigating the intricacies of sand types in sand casting is not merely about understanding raw materials; it's about leveraging this knowledge for superior product outcomes. By emphasizing authenticity, trust in manufacturing processes is cultivated, creating a reliable reputation in the market. Trustworthiness emerges from consistently delivering high-quality cast products, informed by expert knowledge of sand properties and management. In the world of sand casting, such expertise isn’t optional; it is paramount. Post time:Ion . 28, 2025 05:00

Next:Ceramcast sand ball shape for sand casting