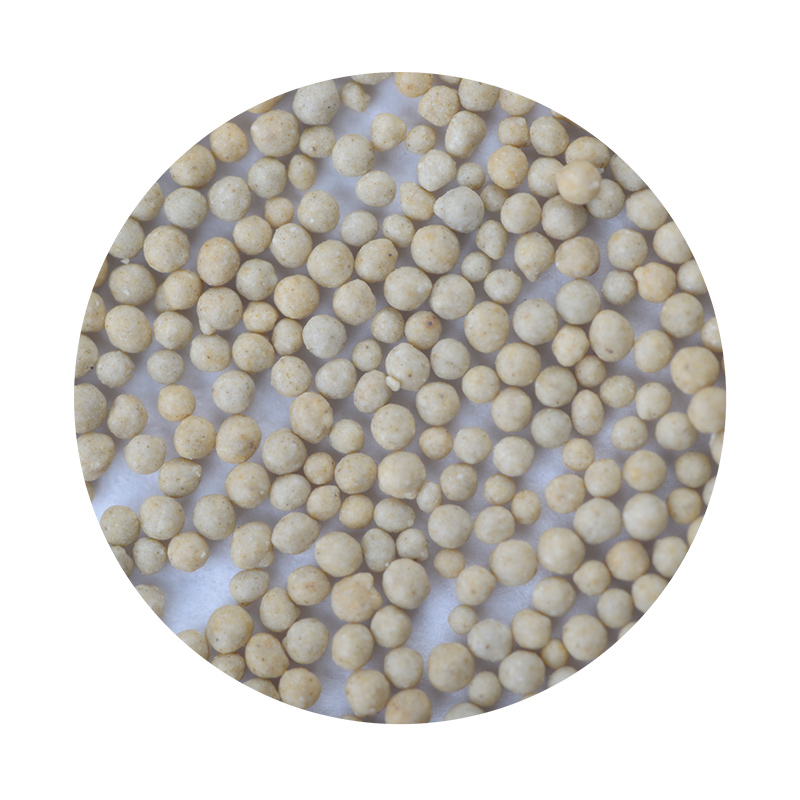

Resin sand, typically used for casting larger parts, deserves specific mention. This sand type involves coating sand particles with a resin that sets upon heating, creating a mold that's both strong and incredibly precise. This property makes resin sand ideal for large and heavy castings that are commonplace in industries like automotive and aerospace. The cost might be higher than green sand, yet the return on investment becomes evident when considering the enhanced dimensional tolerance and surface finish that resin sand molds offer. My experience with resin sand has shown that while initial setup and material costs are steeper, the drastically reduced machining costs and improved casting quality present undeniable benefits for particular applications. Chromite sand brings to the table its distinct thermal conductivity and chilling effect, used predominantly when casting stainless steel blooms or castings where intricate cooling is necessary. Its high thermal conductivity dissipates heat faster than other sands, decreasing the cooling time significantly and improving casting turnover. In plants where I’ve inspected its use, chromite sand has proven invaluable for precision cooling control, which is essential in minimizing warping and other heat-related deformities in high-stress environments. In conclusion, choosing the right sand goes beyond just material economics—it’s an amalgamation of performance, cost-effectiveness, and product specification. The insights gleaned from extensive practical application and continuous adaptation reflect that the future of sand casting is as much about embracing innovation as it is about understanding and leveraging the traditional techniques. With the casting industry evolving rapidly, staying abreast of material advancements through a lens of expertise and trusted experimentation ensures that manufacturers remain at the forefront of precision casting technology. Post time:Chw . 13, 2025 12:00

Next:types of sand used in sand casting