Understanding the Price Dynamics of Resin Coated Sand

Resin coated sand has emerged as a key player in the foundry industry, particularly in the production of high-quality metal castings. The innovative use of resin coatings on sand grains enhances their properties, providing superior strength, dimensional accuracy, and thermal stability. As demand for high-performance castings continues to rise, it is essential to understand the factors influencing the price of resin coated sand.

Understanding the Price Dynamics of Resin Coated Sand

Another influencing factor is the type of resin used for the coating process. Different resins offer varying properties, such as heat resistance and binding strength. Epoxy and phenolic resins are commonly used due to their excellent performance characteristics, but they also come at a higher cost. Manufacturers often face a trade-off between quality and cost, impacting the final pricing structure.

resin coated sand price

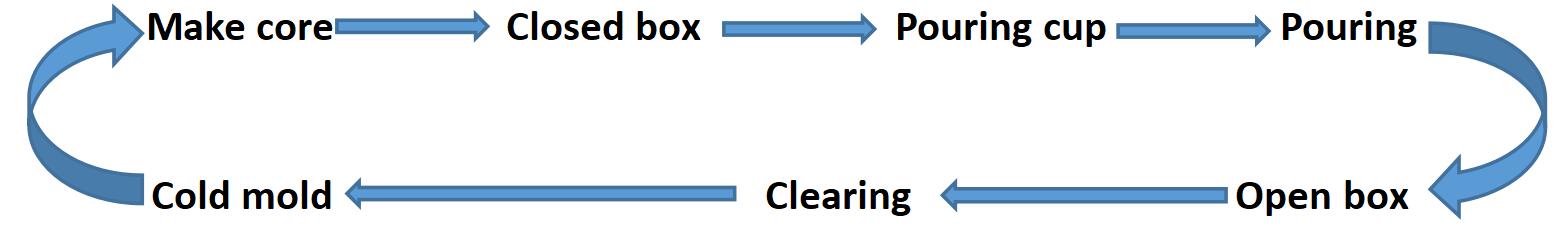

The production process itself also contributes to price fluctuations. The coating of sand with resin involves several steps, including mixing, curing, and screening, all of which require investment in specialized equipment and skilled labor. As technological advancements improve efficiency and reduce waste, manufacturers can optimize production costs. However, initial investments in technology can lead to higher prices in the short term until economies of scale are achieved.

Market dynamics, including supply and demand, play a crucial role in determining prices. The foundry industry has seen fluctuations in demand due to economic cycles, advancements in casting techniques, and changing customer requirements. During periods of high demand, prices for resin coated sand can increase significantly as suppliers strive to meet the needs of foundries. Conversely, during economic downturns, prices may decrease as demand wanes.

Transportation and logistics also impact the final price of resin coated sand. The cost of transporting raw materials and finished products can vary greatly depending on distance, fuel prices, and regional regulations. These logistical challenges can lead to additional costs that manufacturers need to factor into their pricing strategies.

In conclusion, the price of resin coated sand is influenced by a myriad of factors including the quality of raw materials, type of resins used, production methods, market dynamics, and logistical considerations. As the industry continues to evolve, understanding these variables can help stakeholders make informed decisions regarding pricing, sourcing, and inventory management. As technology advances and the market adapts, we can expect to see further developments in the pricing landscape of resin coated sand.

Post time:Medi . 07, 2024 05:39

Next:Golden Sands Company - Quality Products and Services for a Brighter Future