Precision Sand Casting An Overview

Precision sand casting is a widely-used manufacturing process that enables the production of high-quality metal components with intricate geometries and excellent dimensional accuracy. This method involves creating a mold from a mixture of sand and a binding agent, which is then filled with molten metal to produce the desired part. One of the key advantages of precision sand casting is its ability to replicate complex shapes that would be challenging or impossible to achieve through other manufacturing techniques.

The process begins with designing a pattern, often made of a durable material such as metal or plastic. This pattern is used to create a mold cavity in the sand mixture. Unlike traditional sand casting, where the mold can be somewhat imprecise, precision sand casting utilizes advanced techniques such as computer-aided design (CAD) and computer numerical control (CNC) technology to enhance the mold's accuracy. The use of these technologies reduces the dimensional tolerances typically found in conventional casting processes, allowing partners to meet specific engineering requirements.

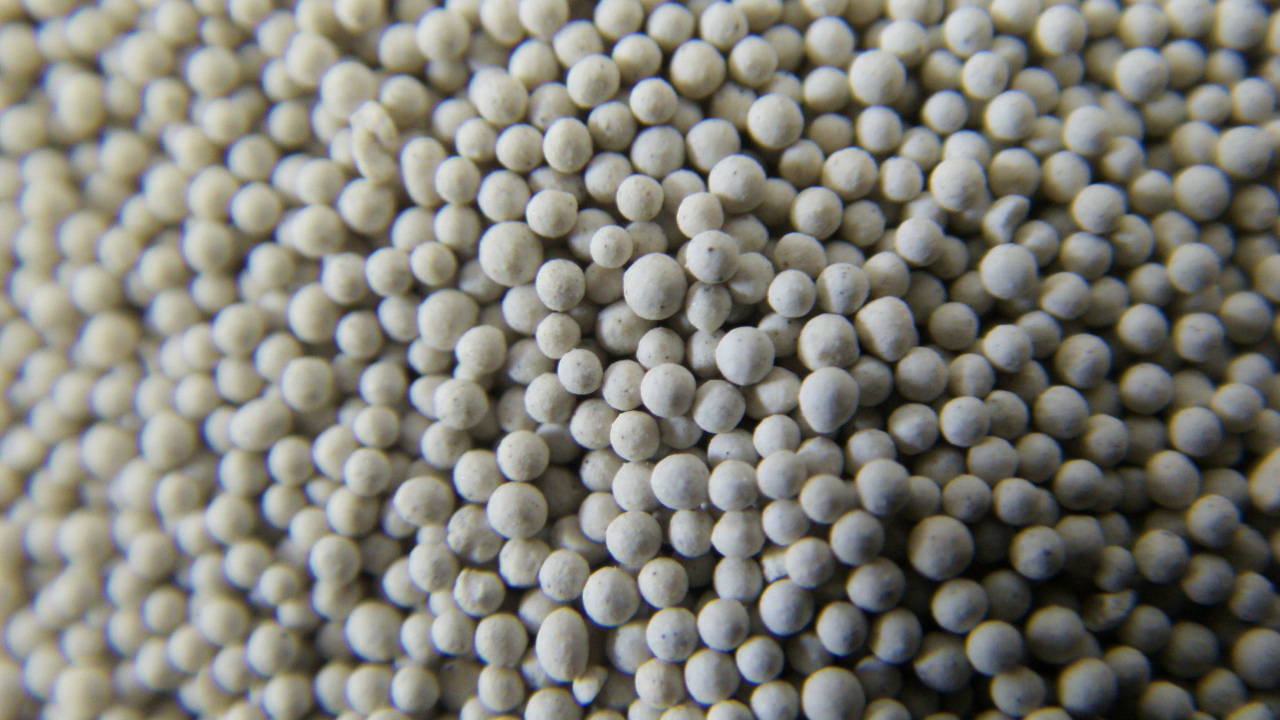

Once the pattern is created, it is embedded in a sand mixture, which may be treated with a resin or other binding agents. After compacting the sand around the pattern, the mold is formed. The next step involves removing the pattern and then heating the mold to strengthen it. Following this, molten metal is poured into the mold cavity, where it solidifies to form the final part.

precision sand casting

The cooling process is crucial; it affects the part's mechanical properties and overall quality. After the metal has cooled sufficiently, the sand mold is broken away to reveal the cast part. This process can yield finely detailed features with smooth finishes, making precision sand casting a popular choice for industries such as aerospace, automotive, and machinery.

Moreover, precision sand casting is not just limited to ferrous metals; it is compatible with a variety of materials, including aluminum, magnesium, bronze, and iron. This versatility makes it suitable for producing components ranging from engine blocks and pump casings to artistic sculptures.

In summary, precision sand casting is a highly effective manufacturing process that combines traditional techniques with modern technology. Its ability to produce high-precision, complex parts makes it an invaluable method in various industries, ensuring that products meet the stringent quality and performance standards of today’s engineering applications. As technology continues to advance, the capabilities and applications of precision sand casting are expected to expand further, solidifying its position as a cornerstone of modern manufacturing.

Post time:Tach . 07, 2024 05:33

Next:Nghệ thuật đánh bóng và làm mịn nhựa từ cát.