The Versatile World of Ceramic Sanding Discs

When it comes to woodworking, metalworking, or general crafting, the tools and materials we choose can significantly affect the quality of our finished products. Among the essential tools for surface preparation and finishing are sanding discs. In recent years, ceramic sanding discs have emerged as a preferred choice for both professional artisans and DIY enthusiasts alike. This article delves into the advantages of ceramic sanding discs, their applications, and best practices for usage.

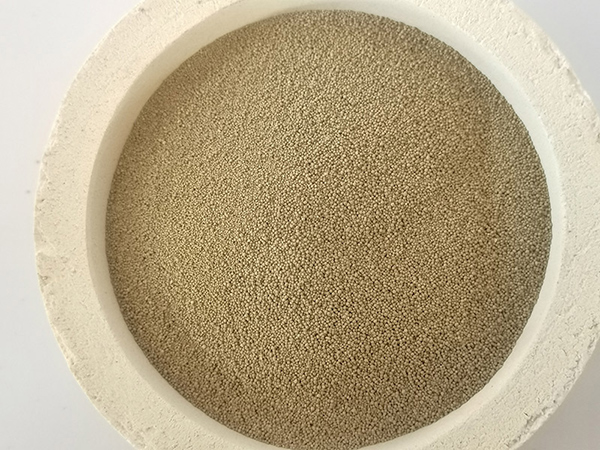

Understanding Ceramic Sanding Discs

Ceramic sanding discs are abrasive tools made with ceramic particles that are bonded to a backing material, typically paper or cloth. These discs are designed for use on various power sanders, including orbital sanders, angle grinders, and belt sanders. The unique properties of ceramic abrasives give these discs certain advantages over traditional aluminum oxide or silicon carbide discs.

Advantages of Ceramic Sanding Discs

1. Durability One of the standout features of ceramic sanding discs is their exceptional durability. The ceramic particles are engineered to withstand higher temperatures and maintain their cutting efficiency longer than other abrasives. This characteristic makes them ideal for heavy-duty applications where standard discs would wear out quickly.

2. Aggressive Cutting Action Ceramic sanding discs are known for their aggressive cutting action. Their sharp edges allow them to remove material quickly and effectively, making them perfect for tasks such as grinding welds or shaping materials. This can significantly improve productivity as users can complete tasks in less time compared to using other sanding discs.

3. Versatility These discs are suitable for a wide range of materials, including wood, metal, plastic, and composites. This versatility makes them invaluable in various industries, from automotive and aerospace to woodworking and metal fabrication.

4. Consistency in Finish Ceramic sanding discs provide a consistent finish across different surfaces. Their uniform abrasive structure leads to even material removal, resulting in a smoother surface that often requires less finishing work. This can save time and resources, especially in professional settings.

5. Resistance to Loading Loading occurs when sawdust, wood particles, or metal shavings clog the surface of the sanding disc, reducing its effectiveness. Ceramic sanding discs have a unique abrasive structure that minimizes loading, allowing them to maintain their cutting efficiency longer.

ceramic sanding discs

Applications of Ceramic Sanding Discs

The applications for ceramic sanding discs are extensive. In woodworking, they are commonly used for shaping and finishing wooden surfaces, whether for furniture-making or cabinetry. In metalworking, these discs are invaluable for grinding and smoothing metal parts, particularly in automotive repair and fabrication processes. Additionally, ceramic sanding discs are effective in surface preparation for painting and coating, ensuring a smooth and properly prepped area for adhesion.

Best Practices for Using Ceramic Sanding Discs

While ceramic sanding discs are robust and versatile, following best practices can enhance their effectiveness and lifespan

- Select the Right Grit Choose the appropriate grit based on your project needs. Coarse grits (36-60) are ideal for aggressive material removal, while finer grits (120-400) are suitable for finishing touches.

- Maintain Proper Pressure Applying excessive pressure can wear out the disc faster and may lead to a less even surface. Let the disc do the work by maintaining a consistent, moderate pressure.

- Use Appropriate Speed Settings Different sanding operations may require varying speeds. Refer to the manufacturer’s recommendations for optimal performance.

- Keep Discs Clean If you notice loading, take a moment to clean the disc. Using a rubber cleaning stick can refresh the abrasive surface, allowing for continued effective use.

Conclusion

Ceramic sanding discs represent a significant advancement in sanding technology, providing durability, efficiency, and versatility across various applications. Whether in a professional shop or a home workshop, incorporating ceramic sanding discs into your toolkit can lead to superior results in your projects. By understanding their benefits and best practices, users can maximize the potential of these exceptional abrasive tools, achieving high-quality finishes with ease.

Post time:Tach . 30, 2024 10:13

Next:Spezifikation für harzbeschichteten Sand