Steel Sand Casting Foundry A Cornerstone of Manufacturing

Steel sand casting is a vital process in the manufacturing industry, providing a versatile and efficient method for producing intricate metal parts. The technique is rooted in the age-old practice of metal casting, where molten metal is poured into a mold made from a sand mixture. This article will explore the significance of steel sand casting foundries, the process involved, and its applications in various industries.

Steel Sand Casting Foundry A Cornerstone of Manufacturing

When the mold is ready, steel is melted in a furnace, often fueled by natural gas or electricity. The temperature of the molten steel can reach up to 1600°C (2900°F). Once the steel is melted, it is poured into the mold cavities. The ability to produce complex shapes in extraordinary dimensions makes steel sand casting an invaluable method in various sectors, from automotive to aerospace, industrial machinery, and heavy equipment manufacturing.

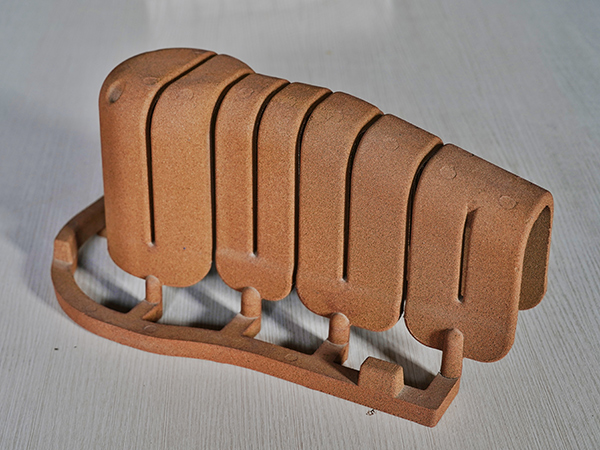

steel sand casting foundry

One of the key advantages of steel sand casting is its adaptability. Foundries can create customized components tailored to specific requirements, which is vital in industries where precision and durability are paramount. Additionally, the process is relatively cost-effective, especially for small to medium-sized production runs. Compared to other casting methods like die casting or investment casting, sand casting often requires less initial investment in tooling and setup.

Furthermore, steel sand casting minimizes waste material. Any unused sand from the casting process can be recycled and reused for future molds. This not only makes the process more economically efficient but also environmentally friendly, aligning with global sustainability efforts.

Quality control is another critical aspect of steel sand casting foundries. Through modern technology, such as computer numerical control (CNC) machining and 3D printing, manufacturers can enhance precision and reduce defects in the casting process. Foundries often conduct rigorous inspection procedures, including metallurgical testing, to ensure the final product meets industry standards and specifications.

In conclusion, steel sand casting foundries play a crucial role in the manufacturing ecosystem, offering a potent combination of flexibility, efficiency, and sustainability. With continuous advancements in technology and methods, the future of steel sand casting looks promising, driving innovation and meeting the demands of various industries. As manufacturers strive for ever-greater efficiencies and quality, steel sand casting remains a cornerstone of modern industrial processes, ensuring the production of high-quality steel components for years to come.

Post time:Zář . 14, 2024 06:28

Next:Памяць матэрыялаў у пясчаным ліцці