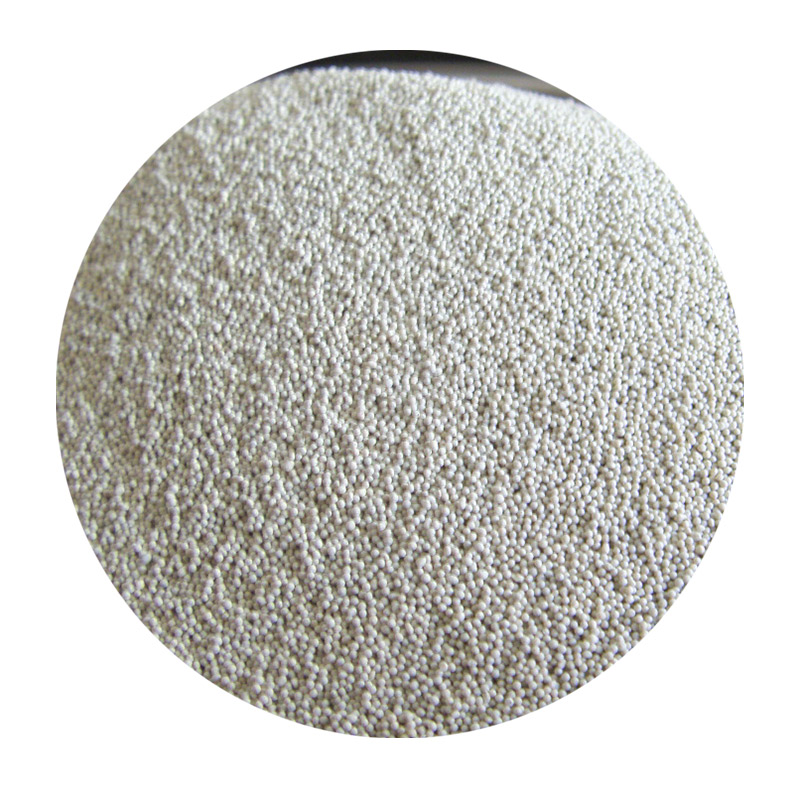

Authorities in the field of sand casting often contribute to the advancement of the technique by experimenting with new sand compositions or enhancing the precision of the mold-making process. For instance, the integration of 3D printing technology to create sand molds and cores has revolutionized the industry by allowing unprecedented accuracy and complexity in design. This innovation not only broadens the possibilities for manufacturers but also significantly reduces lead times and material wastage. Trust in sand casting as a production method also stems from its sustainability and economical nature. The materials used, primarily sand, are reusable and abundant, making the process inherently eco-friendly. Additionally, compared to other casting methods, such as die casting, the initial investment is relatively low, which supports cost-effective scalability for small to medium-sized production runs. In addition to the technical aspects, credibility in sand casting manufacturing is built through rigorous testing and quality assurance processes. Professionals ensure the reliability of their products by implementing thorough inspections and adhering to international standards and certifications, thereby establishing a reputation for delivering consistent and high-quality components. In summary, sand casting metal remains a cornerstone of manufacturing due to its versatility, economic advantages, and capacity for endless innovation. Mastery in this field demands a combination of experience, specialized knowledge, and a commitment to leveraging new technologies. As industries continue to grow and evolve, those who harness the full potential of sand casting will undoubtedly sustain a competitive edge, driving advancements and maintaining the highest standards of product excellence. Post time:Bře . 06, 2025 14:26

Next:sand casting iron