The Advantages of Sand Casting An In-Depth Exploration

Sand casting, also known as sand mold casting, is one of the oldest and most versatile metal casting processes used in industry today. By employing sand as the primary mold material, this technique has stood the test of time due to its numerous advantages, which we will explore in detail.

1. Cost-Effectiveness

One of the most appealing aspects of sand casting is its cost-effectiveness. The materials used for sand casting, primarily sand and binders, are inexpensive and readily available. Unlike other casting methods that may require expensive molds or intricate tooling, sand casting can produce high-quality parts without significant initial investment. This makes it particularly attractive for small production runs and custom parts, allowing businesses to minimize overhead costs.

2. Versatility in Shape and Size

Sand casting is remarkably versatile when it comes to the shapes and sizes of the components it can produce. The process is well-suited for creating complex geometries and large parts that may be challenging to achieve with other casting methods. The ability to mold intricate designs and produce large components is a key advantage for industries such as automotive, aerospace, and heavy machinery, where precision and detail are crucial.

3. Fewer Constraints on Material Types

Another significant advantage of sand casting is the wide range of materials that can be used in the process. This casting method can accommodate various metals and alloys—including iron, aluminum, brass, and steel—allowing manufacturers to choose the best material for their specific application. The adaptability to different material compositions enhances the utility of sand casting across multiple industry sectors.

4. Good Surface Finish and Tolerance

While sand casting may not achieve the same level of surface finish as other casting methods, it is capable of producing parts with acceptable surface quality and tolerances. The use of finer grades of sand and advanced molding techniques has led to improvements in surface characteristics. Additionally, post-processing options such as machining can further enhance the finish, providing flexibility to meet stringent specifications.

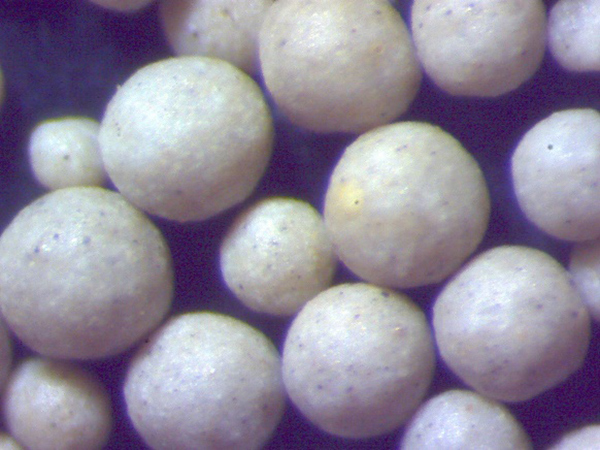

sand casting advantages

5. Ease of Mold Production

Creating molds for sand casting is a relatively straightforward process compared to other casting methods like die casting. The absence of expensive tooling significantly reduces both lead times and production costs. Molds can be created quickly, allowing for rapid prototyping and easy modifications, making sand casting an excellent choice for companies that require agility in their manufacturing processes.

6. High Production Rates

Sand casting can be optimized for batch production, allowing manufacturers to achieve high production rates. Once a mold is created, it can be reused multiple times in sequential production cycles. This efficiency is particularly beneficial for businesses that require consistent output over time, helping to keep pace with market demands.

7. Environmentally Friendly Options

In recent years, advancements in sand casting technology have made the process more environmentally friendly. Reclamation systems have been developed to recycle sand, reducing waste and the need for new raw materials. Moreover, green sand casting, which uses organic binders instead of chemical ones, has gained popularity as a sustainable alternative, further enhancing the process’s appeal.

8. Applications Across Industries

Sand casting is utilized across a diverse range of industries, from automotive to aerospace, agriculture, and consumer products. This broad application spectrum is a testament to the method's versatility and reliability. Components made through sand casting can be found in everything from engine blocks in vehicles to intricate machinery parts and even artistic sculptures, showcasing its adaptability to various needs.

Conclusion

In summary, sand casting remains a vital and advantageous manufacturing process owing to its cost-effectiveness, versatility, material adaptability, and high production rates. As technology continues to evolve, the benefits of sand casting are only expected to grow, enabling it to meet the changing demands of the manufacturing industry. Whether for small-scale projects or large production runs, sand casting presents a reliable solution that balances quality and efficiency, ensuring its place in modern manufacturing.

Post time:Lis . 11, 2024 11:19

Next:what to use to sand resin