Resin Bonded Sand Casting An Innovative Approach in Manufacturing

Resin bonded sand casting is a modern technique in metal forming that significantly enhances the efficiency and accuracy of the traditional sand casting process. This method utilizes a special resin binder that adheres sand grains together, resulting in stronger molds compared to those made with traditional clay-bonded sand. The use of resin in the casting process has gained popularity due to its numerous advantages in producing complex shapes with tight tolerances.

One of the primary benefits of resin bonded sand casting is the superior surface finish it offers. The resin binder creates molds that are more rigid and finer, allowing for smoother surface finishes on cast parts. This is particularly advantageous for industries that require high precision, such as automotive and aerospace sectors, where even the slightest imperfection can lead to significant performance issues. The improved surface quality also reduces the need for extensive machining afterward, saving both time and costs.

Moreover, resin bonded sand casting allows for faster production cycles. The molds cure at room temperature or through the application of heat, which accelerates the casting process and reduces the lead time significantly. This characteristic is particularly beneficial in environments where quick turnaround times are essential, such as custom parts manufacturing or repair applications. The ability to rapidly produce high-quality molds makes this method particularly attractive in today’s fast-paced manufacturing landscape.

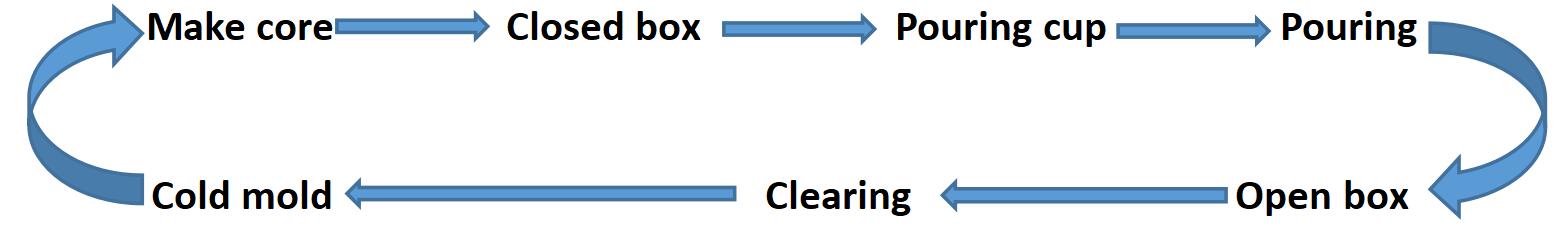

resin bonded sand casting

Another notable advantage is the versatility of the resin bonded sand. The technique is compatible with a wide range of metals, including aluminum, iron, and bronze, which broadens its applicability across various industries. Additionally, because the sand can be reused after the castings are removed, resin bonded sand casting promotes sustainability by minimizing waste and reducing the overall material consumption.

However, it is essential to consider that resin bonded sand casting does come with its challenges. One significant concern is the environmental impact of the resin materials used. Traditional resins can emit volatile organic compounds (VOCs) during the curing process, leading to health and safety concerns for workers. To address this issue, manufacturers are increasingly looking towards more eco-friendly resin options, such as those based on bio materials or low-VOC formulations.

In conclusion, resin bonded sand casting represents a significant advancement in the field of manufacturing, offering improved product quality, faster production times, and greater design flexibility. As industries continue to seek ways to enhance efficiency and sustainability, this innovative casting method is likely to play an increasingly prominent role. With ongoing research and development focused on minimizing environmental impacts, resin bonded sand casting is poised to become a staple in modern manufacturing practices. By harnessing the advantages of this technique, manufacturers can achieve superior outcomes while aligning with contemporary sustainability goals, ultimately leading to a more efficient and responsible production process.

Post time:Zář . 03, 2024 02:42

Next:sand casting cost