The Importance of Sand Casting in Modern Manufacturing

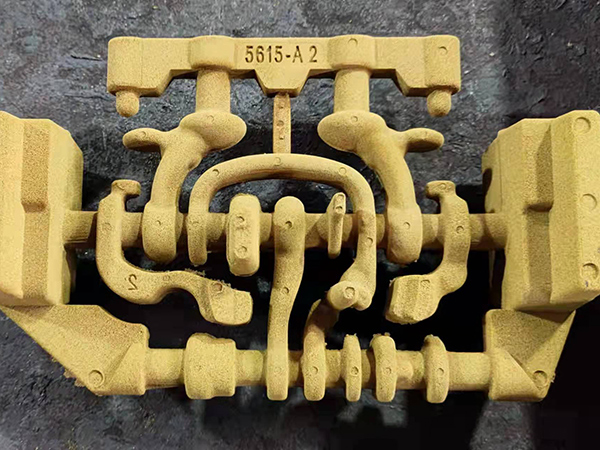

Sand casting, a time-honored metal casting technique, has retained its relevance in modern manufacturing due to its versatility, cost-effectiveness, and ability to produce intricate shapes. This method of casting involves creating a mold from a mixture of sand, water, and a binding agent. By pouring molten metal into these molds, manufacturers can create a wide array of components used in various industries, including automotive, aerospace, and construction. Understanding the significance of sand casting provides insight into its enduring role in both traditional and contemporary manufacturing practices.

Versatility in Design and Material Use

One of the most compelling advantages of sand casting is its ability to accommodate a wide range of designs and materials. Unlike some casting methods that may restrict you to specific geometries or alloys, sand casting can produce complex shapes and is compatible with numerous metals, including aluminum, brass, iron, and steel. This versatility allows engineers and designers to push the boundaries of creativity and innovation, resulting in components that meet unique specifications and performance requirements. The flexibility in designing molds further enhances the method's appeal, as it enables manufacturers to produce both small-scale prototypes and large-scale production runs.

Cost-Effectiveness and Accessibility

Another key factor contributing to the importance of sand casting is its cost-effectiveness. The materials needed for sand casting, primarily sand, are relatively inexpensive and widely available. This makes the process accessible to small and medium-sized enterprises (SMEs), which may not have the capital required for more advanced casting techniques. Additionally, the sand casting process allows for a relatively low initial investment in equipment, further democratizing access to manufacturing capabilities. As a result, sand casting remains a popular choice for start-ups and smaller businesses looking to create custom components without incurring prohibitive costs.

Rapid Prototyping Capabilities

importance of sand casting

In the fast-paced modern manufacturing landscape, the ability to prototype quickly is essential. Sand casting facilitates rapid prototyping because it allows for quick adjustments and iterations in the design process. Engineers can create molds in a short time and modify them as needed, reducing the time from concept to finished product. This agility is crucial for industries that require constant innovation and adaptation, as it allows businesses to respond swiftly to changing consumer demands and technological advancements.

Environmental Considerations

With increasing awareness of environmental sustainability, sand casting has an advantage due to its relatively low environmental impact compared to other casting methods. The sand used in molds can often be reused multiple times, which minimizes waste. Additionally, the energy consumption in sand casting can be lower than in some alternative processes, making it a more environmentally friendly option. As industries strive to adopt greener practices, sand casting stands out as a responsible choice that aligns with sustainability goals.

The Role of Sand Casting in Industry Trends

Sand casting not only benefits traditional manufacturing but also plays a vital role in emerging trends such as additive manufacturing and the Internet of Things (IoT). The integration of sensors and digital technologies in sand casting processes is revolutionizing quality control and production efficiency. By employing data analytics and real-time monitoring, manufacturers can enhance the precision and consistency of cast products, further solidifying sand casting's place in the future of manufacturing.

Conclusion

In conclusion, the importance of sand casting in modern manufacturing cannot be overstated. Its versatility, cost-effectiveness, rapid prototyping capabilities, and environmental considerations make it an essential process for diverse industries. As the manufacturing landscape continues to evolve, sand casting remains a foundational technique that enables innovation while meeting the demands of today’s market. As we look to the future, the continued integration of new technologies with traditional methods like sand casting will undoubtedly open new avenues for growth and excellence in manufacturing.

Post time:Zář . 27, 2024 05:17

Next:Sandstøbeteknologi En omfattende guide til fremstilling og anvendelse af sandstøbninger