The Evolution of 3D Printed Sanding Solutions

In recent years, the realm of 3D printing has expanded significantly, paving the way for innovative applications across various industries. One such advancement is the development of 3D printed sanding tools. This novel approach merges traditional sanding techniques with cutting-edge technology, offering a range of benefits that enhance efficiency and precision in surface finishing.

The Evolution of 3D Printed Sanding Solutions

One of the primary advantages of 3D printed sanding tools is their ability to be customized for various shapes, sizes, and materials. Traditional sanding tools are often limited in their design capabilities; however, 3D printing allows for intricate designs that enhance the effectiveness of the tool. For example, a 3D printed sander can feature complex geometries that conform to the object being sanded, allowing for even pressure distribution and minimizing the risk of damaging delicate surfaces. This is particularly useful in industries such as woodworking and model making, where precision is paramount.

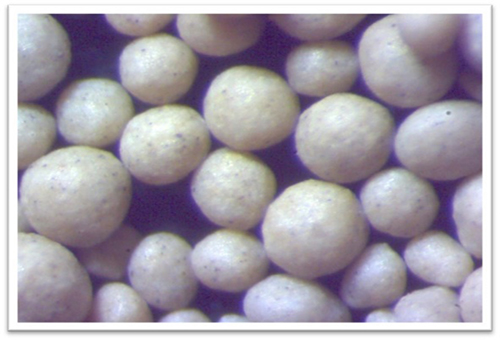

3d printed sanding

Moreover, 3D printing enables the production of sanding tools that integrate multiple functions into a single device. For instance, a sanding tool can be designed to include built-in dust collection features, which helps in maintaining a clean workspace and reduces health hazards associated with inhaling dust particles. Such innovations not only improve the working environment but also contribute to better overall health for workers in industries reliant on sanding.

Another noteworthy aspect of 3D printed sanding solutions is their cost-effectiveness. Traditional manufacturing methods often involve high material costs and lead times. In contrast, 3D printing reduces material waste significantly, as the additive manufacturing process builds objects layer by layer. Additionally, the ability to produce tools on-demand means that companies can respond to specific needs without having to invest in large inventories of tools that may or may not be used.

The environmental impact of 3D printed sanding tools cannot be overlooked either. As sustainability becomes a priority in manufacturing, the shift towards 3D printing can contribute to greener practices. By minimizing waste and allowing for the use of biodegradable or recyclable materials, 3D printed tools can help companies reduce their carbon footprint while still achieving high-quality results.

In conclusion, the emergence of 3D printed sanding solutions marks a significant step forward in the field of surface finishing. The ability to customize tools, integrate multiple functions, reduce costs, and promote sustainability makes 3D printed sanding tools a compelling choice for industries looking to enhance their operations. As technology continues to evolve, we can expect even more innovative developments in this space, paving the way for future advancements in design and manufacturing. Embracing such technologies will undoubtedly lead to more efficient, precise, and environmentally friendly practices in the world of sanding and beyond.

Post time:Říj . 15, 2024 12:58

Next:Leading Manufacturer of High-Quality Resin Coated Sand for Industrial Applications