The Importance and Applications of Sand-Resin Mixtures in Modern Industries

Introduction

Sand-resin mixtures have emerged as a crucial component in various industrial applications, particularly in the fields of construction, foundry work, and even in advanced manufacturing processes. This article delves into the composition, advantages, and applications of sand-resin mixtures, highlighting their significance in meeting modern demands for durability and efficiency.

Composition of Sand-Resin Mixtures

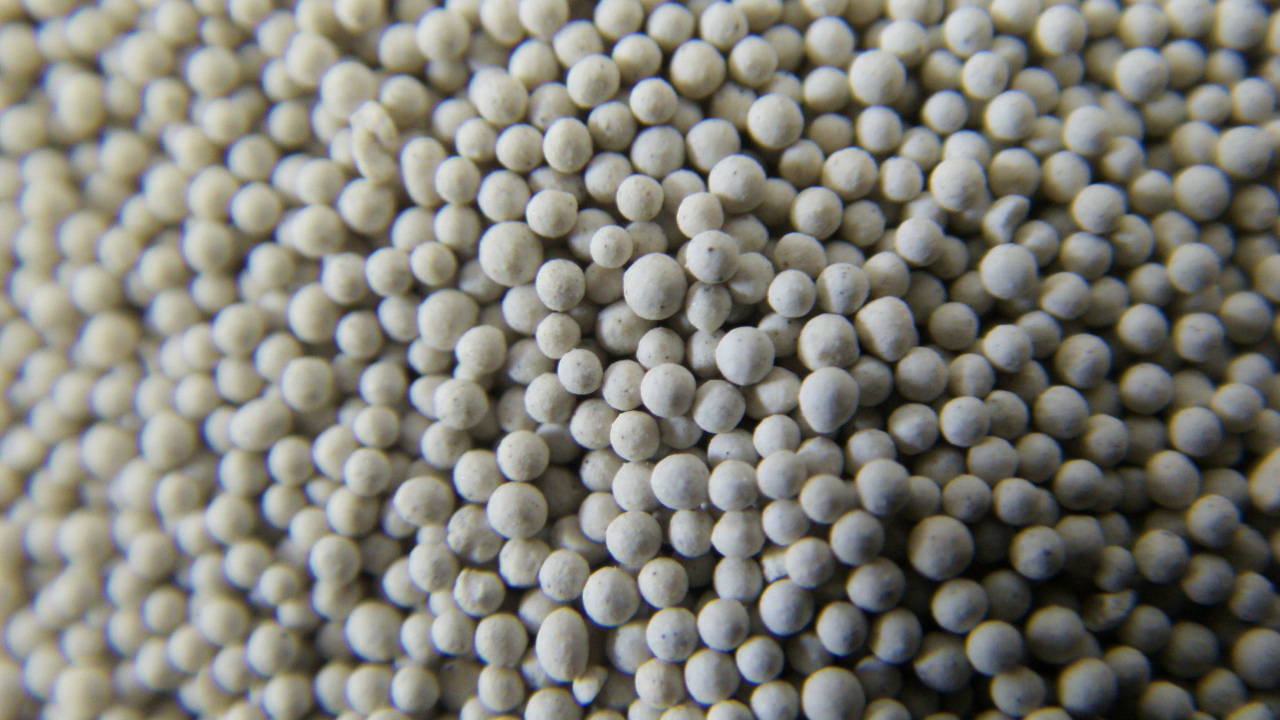

At its core, a sand-resin mixture primarily consists of granular sand particles combined with a synthetic resin binder. The type of resin may vary, but common choices include phenolic, epoxy, and polyurethane resins. The selection of resin impacts not only the physical properties of the mixture but also its curing time and overall performance.

The sand used in these mixtures usually consists of quartz or other similar materials, ensuring that it has the necessary characteristics needed for specific applications. The ratio of sand to resin is meticulously controlled based on the intended use, with typical mixtures ranging from 70% sand to 30% resin by volume. This careful balance ensures optimal strength and flexibility in the final product.

Advantages of Sand-Resin Mixtures

One of the primary advantages of using sand-resin mixtures is their superior mechanical properties. These mixtures exhibit high compressive and tensile strength, making them suitable for demanding environments. Moreover, the use of synthetic resins enhances the corrosion resistance of the product, prolonging its life and reducing maintenance costs.

sand resin mixture

Additionally, sand-resin mixtures offer excellent dimensional stability, which is critical in applications where precision is paramount. The mixtures can be formulated to possess varying degrees of hardness, allowing for customization based on specific needs. Furthermore, the curing process can be accelerated through the application of heat or catalysts, enabling faster production cycles.

Applications in Various Industries

1. Foundry Work One of the most significant applications of sand-resin mixtures is in the foundry industry, where they are used to create mold and core systems. The resin binds the sand particles, producing molds that have exceptional detail and surface finish. This technology is crucial for producing intricate metal components with high precision, such as those used in the automotive and aerospace industries.

2. Construction In construction, sand-resin mixtures are often used to produce high-performance concrete and structural components. They can be utilized in the production of precast elements, ensuring that structures meet rigorous safety codes and withstand environmental challenges. The durability of these mixtures contributes to longer-lasting infrastructures.

3. 3D Printing The rise of additive manufacturing has also seen the integration of sand-resin mixtures in 3D printing technologies. These mixtures provide an efficient medium for producing complex geometries that are otherwise difficult to achieve with traditional methods. As the technology evolves, the potential applications of sand-resin mixtures in this realm continue to grow.

4. Art and Design Beyond industrial applications, sand-resin mixtures are increasingly used in artistic endeavors. Artists and designers harness the unique properties of these mixtures to create sculptures, decorative panels, and other creative projects, leveraging the aesthetic appeal and durability of the final product.

Conclusion

The versatility and robust characteristics of sand-resin mixtures make them indispensable across various sectors. Their ability to enhance the mechanical and physical properties of products positions them as a favorable choice in both traditional manufacturing and advanced industries. As technology progresses, the understanding and application of sand-resin mixtures will continue to evolve, opening up new possibilities for innovation and efficiency. Whether in foundries or creative arts, the impact of these mixtures is profound and far-reaching, shaping the future of numerous industries.

Post time:Nov . 27, 2024 04:30

Next:Techniques for Smoothing and Finishing Your 3D Printed Models