Sanding 3D Printed Objects A Guide to Achieving Smooth Finishes

In the realm of 3D printing, achieving a high-quality finish on printed objects is often a key concern for both hobbyists and professionals. While 3D printing technology allows for the rapid production of intricate designs and prototypes, it often leaves a surface that can be rough or uneven due to the layering process. Sanding has emerged as one of the most effective methods for refining the surface quality of 3D printed objects.

Understanding the Importance of Sanding

Sanding involves the use of abrasive materials to remove imperfections and create a smoother surface. The primary reasons for sanding 3D printed objects include aesthetic appeal, improved paint adhesion, and a more pleasant tactile experience. A smoothly finished object not only looks better but also feels better in hand, which is particularly important for products intended for consumer use.

Choosing the Right Tools

When it comes to sanding 3D printed objects, the choice of tools is crucial. Sandpaper is the most common option, available in various grits ranging from coarse to very fine. For most 3D prints, starting with a medium grit (around 150-220) is advisable to remove the most significant imperfections. As you progress, shifting to finer grits (up to 1000 or higher) can help achieve that mirror-like finish.

In addition to sandpaper, consider using sanding blocks or sponges for better control and even pressure application. For intricate parts, precision sanding tools like rotary sanders can also be effective.

Techniques for Effective Sanding

Sanding 3D printed objects requires a systematic approach to ensure a smooth finish without over-sanding. Here are some techniques to keep in mind

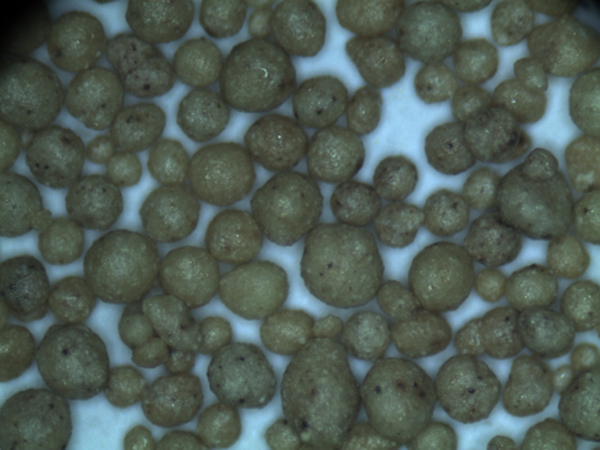

sanding 3d printed objects

1. Start with Coarse Grit Begin with a coarse grit paper to remove the most pronounced surface irregularities. Be sure to sand evenly to avoid creating new grooves.

2. Progressively Finer Grits After achieving a relatively smooth surface with coarse grit, gradually move to finer grits. This progression minimizes the risk of scratches that may remain visible after finishing.

3. Maintain an Even Pressure Apply consistent, even pressure while sanding to avoid creating uneven surfaces. This is crucial, especially on curved or detailed areas.

4. Wet Sanding For certain materials like PLA, wet sanding can enhance the finish while reducing dust and preventing clogging of the sandpaper. Wetting the surface also reduces heat buildup, minimizing the risk of warping.

5. Frequent Checks Regularly examine your progress under good lighting. This helps you catch areas that need more attention and prevents oversanding.

Finishing Touches

Once the desired smoothness is achieved, it’s often beneficial to apply a finish or coating. Options include paints, primers, or epoxy resins, which not only enhance appearance but also provide additional protection to the surface.

In conclusion, sanding 3D printed objects is an essential step towards achieving professional-quality finishes. With the right tools, techniques, and a little patience, you can transform rough prints into smooth, attractive pieces that meet your standards and impress others. Whether for a personal project or a prototype for a client, investing time in sanding pays off with superior results.

Post time:Set . 15, 2024 07:11

Next:Lost Foam Casting Method - Precision, Efficiency, and Innovation