Understanding Sand Cast Iron Properties and Applications

Sand cast iron, a popular form of cast iron, is known for its excellent casting properties, which make it suitable for a wide range of industrial applications. The process of sand casting involves pouring molten iron into a mold made of sand, allowing it to solidify and take the shape of the mold. This technique has been utilized for centuries, dating back to ancient civilizations where artisans would craft intricate designs and functional tools.

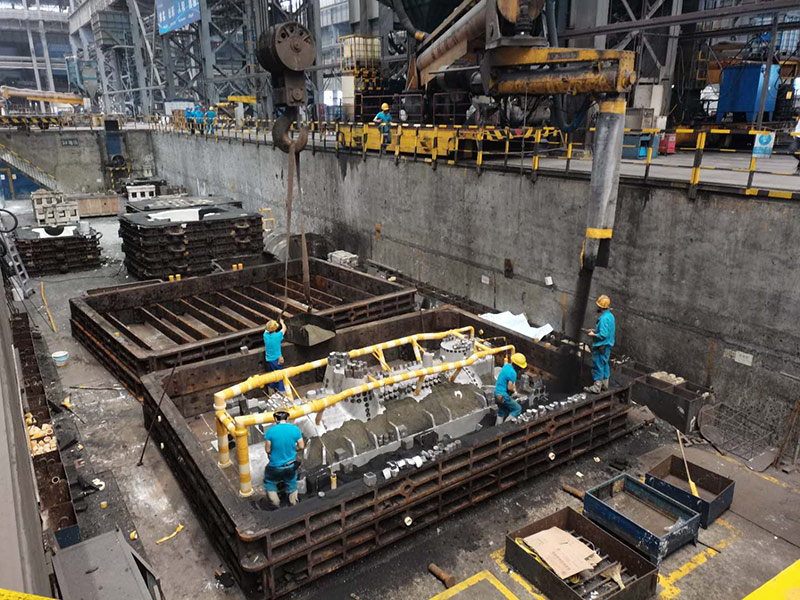

One of the primary advantages of sand cast iron is its versatility. It can be cast into intricate shapes and sizes, making it an ideal material for producing components with complex geometries. The ability to create both large and small parts makes sand cast iron a favored choice in industries like automotive, aerospace, and general manufacturing. Items such as engine blocks, machine bases, and various other components can be efficiently produced using this method.

sand cast iron

Sand cast iron is categorized into several types based on its composition, including gray iron, ductile iron, and white iron. Gray iron is the most common and is characterized by its excellent casting properties and machinability. It contains a high amount of graphite, which contributes to its unique properties, such as good wear resistance and vibration dampening. Ductile iron, also known as nodular iron, is known for its enhanced strength and ductility, making it suitable for demanding applications like pipes and heavy machinery parts. On the other hand, white iron has a high carbon content and is known for its hardness, making it suitable for wear-resistant applications.

The sand casting process typically involves several stages, including pattern making, molding, pouring, and finishing. The pattern, which is a replica of the final product, is created using materials like wood or metal. It is then placed in a sand mold, and molten iron is poured into the cavity. Once the iron has cooled and solidified, the mold is broken away to reveal the cast iron product. Final finishing processes, such as machining and surface treatment, are often necessary to achieve the desired surface quality and dimensional accuracy.

In conclusion, sand cast iron remains a crucial material in modern manufacturing due to its excellent casting properties, versatility, and the ability to create complex shapes. Whether it’s used in automotive components or industrial machinery, the unique characteristics of sand cast iron continue to meet the diverse needs of various industries, making it an indispensable part of contemporary engineering and manufacturing processes.

Post time:Ago . 28, 2024 16:46

Next:Eigenschaften von Gießsand