The Uses of Resin Coated Sand A Versatile Material in Modern Manufacturing

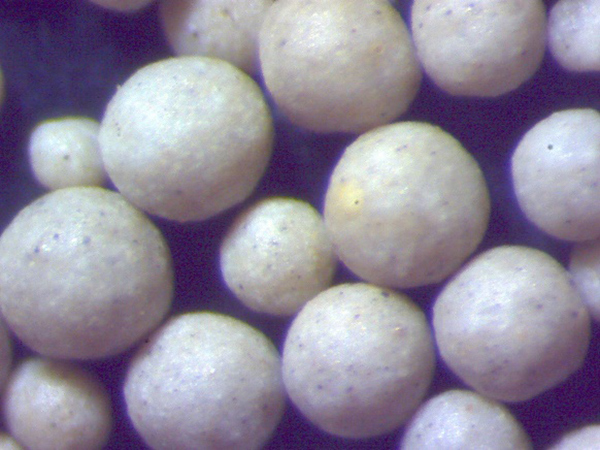

Resin coated sand is an innovative product that has transformed various sectors of the manufacturing and casting industry. This material is made by coating standard sand grains with a thermosetting resin, which enhances the physical properties of the sand and creates a durable, high-performance solution for a wide range of applications. The unique characteristics of resin coated sand make it an ideal choice for foundries, construction, and even specialized industries such as aerospace and automotive manufacturing.

The Uses of Resin Coated Sand A Versatile Material in Modern Manufacturing

Another important application of resin coated sand is in the production of cores for castings. Cores are used to create internal cavities in castings and must be durable enough to withstand the high temperatures of molten metal. Resin coated sand offers excellent thermal resistance, allowing it to maintain its integrity even under extreme conditions. This durability ensures that the cores maintain their shape and provide the required accuracy, leading to higher quality end products.

resin coated sand uses

In addition to the foundry sector, resin coated sand is also utilized in the construction industry. It is often used in the production of concrete and other construction materials, where its added strength and stability can significantly enhance the properties of the final product. The use of resin coated sand in concrete mixtures can improve the compressive strength, reduce permeability, and enhance the overall durability of the structure. This makes it particularly valuable in environments subject to harsh weather conditions or heavy loads.

Moreover, the aerospace and automotive industries have also embraced resin coated sand for producing components that require precise dimensions and exceptional surface quality. For example, in aerospace applications, where weight and performance are critical, using high-quality cast components made with resin coated sand can lead to improved fuel efficiency and overall performance. Similarly, in the automotive sector, it can be used to produce lightweight and sophisticated engine components that contribute to better performance and efficiency.

The versatility of resin coated sand extends beyond traditional industries as well. Its properties make it suitable for specialized applications such as art casting and making decorative items. Artists and designers use resin coated sand to create intricate molds and casts, allowing for a high level of detail and artistry in their work.

In conclusion, resin coated sand is a multifaceted material that has found extensive use across a variety of industries due to its superior properties. From enhancing the quality of metal castings in foundries to improving structural integrity in construction, the applications of resin coated sand are vast and continue to grow. As technology advances and industries seek more efficient and sustainable solutions, the demand for resin coated sand will likely increase, solidifying its place as a vital component in modern manufacturing processes.

Post time:Set . 30, 2024 01:40

Next:Sand casting prosesinin nə olduğunu öyrənmək