Different Types of Sand Casting

Sand casting is one of the oldest and most versatile metal shaping processes known, and it remains widely used in the manufacturing industry today. This technique involves creating a mold from sand to pour molten metal into it, allowing for the production of complex shapes with a variety of materials. The flexibility and accessibility of sand casting make it a preferred choice for many metal fabrication tasks. There are several types of sand casting processes, each with its unique characteristics and applications. Below, we explore some of the most common types of sand casting.

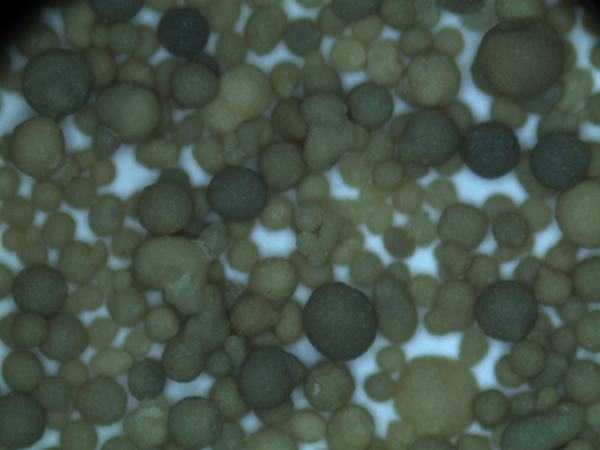

1. Green Sand Casting

Green sand casting is the most traditional method of sand casting. The term green refers to the moisture content in the sand mixture, which typically consists of silica sand, clay, water, and other additives. This type of sand is easy to mold and provides excellent flexibility and strength during the casting process. The mold is created by packing damp sand around a pattern, which is typically made from metal or wood. Once the mold is formed, it is allowed to set and dry before molten metal is poured into it. Green sand casting is favored for its cost-effectiveness and simplicity, making it suitable for both small-scale and large-scale production runs.

2. Dry Sand Casting

Unlike green sand casting, dry sand casting uses sand that has been dried and baked in an oven. This process helps to strengthen the mold, making it more suitable for casting metals at higher temperatures. The dried sand is mixed with a bonding agent, usually a resin, and then pressed into a mold. The benefit of dry sand is its ability to produce smoother surface finishes compared to green sand molds. However, dry sand casting can be more expensive due to the additional steps required for drying and resin bonding. This method is particularly useful in applications where surface quality is critical, such as in the aerospace and automotive industries.

different types of sand casting

Shell mold casting involves creating a thin shell of sand around a metal pattern coated with a resin binder. This process begins by heating the metal pattern, which is then coated with the resin-bonded sand. The heat causes the resin to bond and solidify, forming a shell. Once the shell is sufficiently thick, it is removed from the pattern, and the two halves of the shell are assembled to form a mold. This technique allows for high precision and intricate detail in the final castings. Shell mold casting is often used for smaller components that require tight tolerances and excellent surface finishes, making it popular in industries like machinery manufacturing.

4. Nobake Sand Casting

Nobake sand casting, also known as air-set sand casting, uses a sand mixture that does not require baking or drying in an oven. Instead, the sand is mixed with a chemical binder that hardens through a curing process. This method is advantageous because it allows for the production of large and complex castings without the need for high-temperature molds. Nobake sand casting is particularly useful for producing large components such as engine blocks and heavy machinery parts. While it may require more time to set compared to green sand casting, its ability to handle complex shapes and large sizes makes it a favored option in certain manufacturing scenarios.

5. Lost Foam Casting

Lost foam casting is a unique method wherein a foam pattern is coated with a sand mixture to create a mold. Once the mold is formed, molten metal is poured directly onto the foam pattern, causing it to vaporize and leave behind the desired shape in the sand. This technique allows for very intricate designs and complex geometries that would be challenging to achieve with traditional casting methods. Lost foam casting is often used in automotive applications and for producing intricate parts with deep cavities.

Conclusion

Sand casting remains an essential method for metal fabrication, offering various techniques suited for different applications. Each type of sand casting—green sand, dry sand, shell mold, nobake, and lost foam—has distinct advantages and is selected based on requirements such as shape complexity, surface finish quality, and production volume. With advancements in materials and technology, sand casting continues to evolve, ensuring its place in modern manufacturing processes. As industries demand more precise and efficient methods of production, understanding these different types of sand casting will be vital for engineers and manufacturers alike.

Post time:Set . 30, 2024 03:57

Next:Roestvrijstalen zandgieten in een hoogwaardige gieterij voor diverse toepassingen