Sintered Sand A Revolutionary Material in Modern Manufacturing

Sintered sand, a composite material that has gained traction in various industrial applications, stands at the intersection of innovation and sustainability. Its unique properties and versatility make it an intriguing subject for both researchers and manufacturers. This article explores the characteristics, manufacturing processes, applications, and advantages of sintered sand, shedding light on its role in advancing modern engineering.

What is Sintered Sand?

Sintered sand refers to a material created through a process called sintering, where sand particles are heated to a temperature below their melting point, allowing them to bond together. This results in a solid object that retains the shape of the original sand mold or form. The sintering process not only enhances the mechanical properties of the sand but also improves its thermal stability and structural integrity. The result is a durable and lightweight material that can be tailored to meet specific requirements.

Manufacturing Process

The manufacturing of sintered sand involves several crucial steps

1. Raw Material Selection High-purity silica sand is typically used due to its excellent thermal and chemical properties. Additives such as binders can be incorporated to enhance the bonding process.

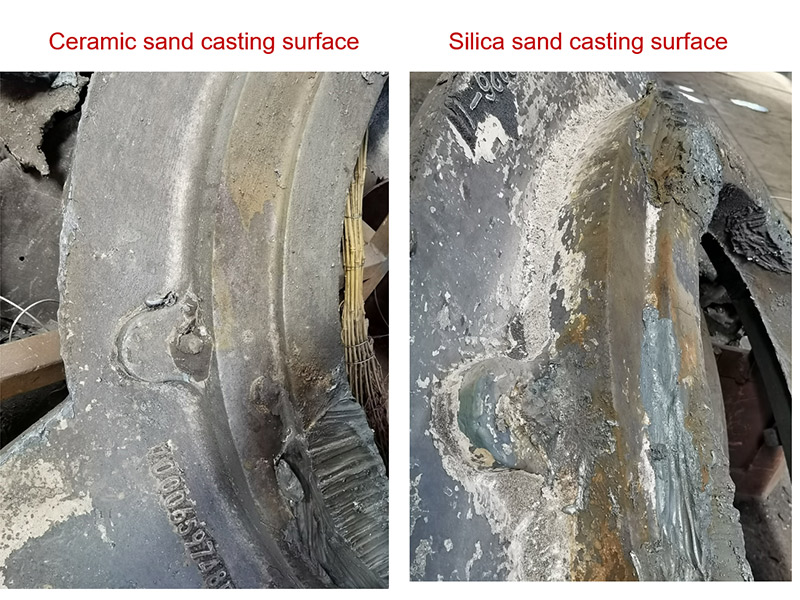

2. Mixing and Molding The sand is thoroughly mixed with any necessary additives before being placed into a mold. This can be done using a variety of techniques, including 3D printing or traditional sand casting.

3. Sintering Once the mold is prepared, it is subjected to high temperatures in a controlled environment. During this phase, the sand particles begin to fuse, forming a solid structure. The sintering temperature and time can be adjusted to achieve desired material properties.

4. Cooling and Finishing After sintering, the material is allowed to cool slowly. It may undergo additional treatments such as grinding or surface finishing to meet specific design criteria.

Applications of Sintered Sand

Sintered sand has a multitude of applications across various industries

sintered sand

- Aerospace The lightweight nature of sintered sand makes it an ideal choice for parts requiring both strength and low weight

. Components such as casing and internal structures in aircraft benefit from its properties.- Automotive In the automotive sector, sintered sand is used for making engine parts, brake components, and other critical components that demand high thermal stability and durability.

- Construction Sintered sand can also be employed in the construction industry for producing bricks and blocks that are lighter yet stronger than traditional materials, promoting sustainability in building practices.

- Art and Design The versatility of sintered sand allows artists and designers to create intricate sculptures and components with high detail and strength, expanding the boundaries of creative expression.

Advantages of Sintered Sand

The advantages of using sintered sand in manufacturing are manifold

- Resource Efficiency Sintering allows for the effective use of natural resources. By maximizing the potential of available sand, manufacturers can reduce waste and minimize the environmental impact of their production processes.

- Cost-Effective The production of sintered sand components can be less expensive over time compared to traditional materials, particularly when factoring in longevity and performance.

- Customization The sintering process allows for the creation of components with precise specifications, tailored to meet specific performance requirements of different applications.

- Sustainability With a focus on renewable and recyclable materials, sintered sand contributes to a more sustainable manufacturing paradigm, aligning with global efforts to reduce carbon footprints.

Conclusion

Sintered sand is proving to be a game-changer in the manufacturing world, offering a blend of durability, versatility, and sustainability. As industries continue to seek innovative solutions that reduce waste and enhance efficiency, sintered sand is poised to play an increasingly vital role in the future of material science. Its potential applications, from aerospace to construction, reaffirm its significance and underscore the importance of embracing advanced materials in modern engineering practices.

Post time:des. . 24, 2024 19:40

Next:ceramic sanding discs