How to Make Foundry Sand

Foundry sand is a crucial material used in metal casting. It provides a high-quality surface finish and ensures the casting process is efficient and effective. Utilizing the right type of sand, along with the appropriate preparation techniques, can significantly enhance the quality of the finished product. In this article, we will explore how to make foundry sand step-by-step, including the materials needed and techniques to follow.

Materials Needed

1. Silica Sand The primary ingredient for foundry sand is silica sand. It should be round-grained and free from impurities. 2. Binding Agents Common binding agents include clay (bentonite) and water. These help the sand stick together and maintain its shape when packed around the mold. 3. Additives Depending on the specific casting process, various additives can be used to improve the properties of the sand. These may include coal dust, chemical binders, or oils to enhance performance. 4. Mixing Equipment A mixer or a sand muller is necessary to ensure that the sand, binders, and additives are evenly distributed. 5. Sieve A sieve may be used to separate larger particles and ensure a consistent grain size.

Step-by-Step Process

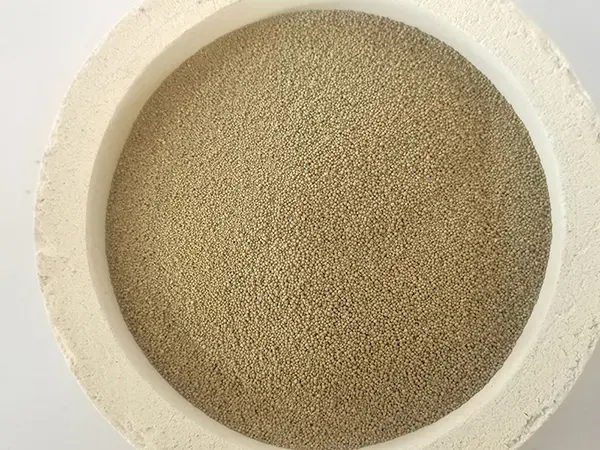

1. Selecting the Sand Start by selecting high-quality silica sand. The sand should be clean and free from contaminants like clay, silt, and organic materials. Check for a uniform granule size, which typically ranges from 0.2 to 0.5 mm for foundry use.

how to make foundry sand

2. Sifting the Sand Use a sieve to sift the silica sand and eliminate any larger particles or impurities. This ensures uniformity in mixing and allows for a better mold creation.

3. Mixing - In a large mixing container or muller, combine the sifted silica sand with the appropriate amount of clay. A common mixture ratio is 5-10% clay to the amount of sand. The clay acts as a binder, providing strength and cohesion to the mold. - Gradually add water to the mixture. The ideal moisture content is usually between 3-5%. Adding too much water can lead to problems with mold strength, while too little can result in poor compaction. - Mix thoroughly using your equipment or by hand to ensure that the clay is evenly distributed throughout the sand.

4. Testing the Mixture - After mixing, it’s important to test the sand to ensure it has the right properties. Perform a clump test by taking a handful of the mixture and squeezing it. It should hold its shape without crumbling easily. If it breaks apart, add more clay and water as needed. - Additionally, check for the consistency of the sand by performing a “flow test.” This will determine how well the sand will pour into a mold and hold detail.

5. Storing the Sand Once the sand reaches the desired consistency, it should be stored in a dry place to prevent moisture absorption. If not used immediately, seal it in airtight containers to maintain its quality.

Conclusion

Making foundry sand is a delicate process that requires careful attention to the materials and methods used. By selecting high-quality silica sand, using the right proportions of clay and water, and conducting thorough testing, one can create an effective foundry sand that will significantly enhance the castings produced. Whether you are a hobbyist maker or a professional in metal casting, understanding how to properly prepare this essential material will ensure quality production and successful results in your metalwork projects.

Post time:set. . 27, 2024 23:07

Next:Швидке піщане лиття переваги та технологічні особливості процесу.