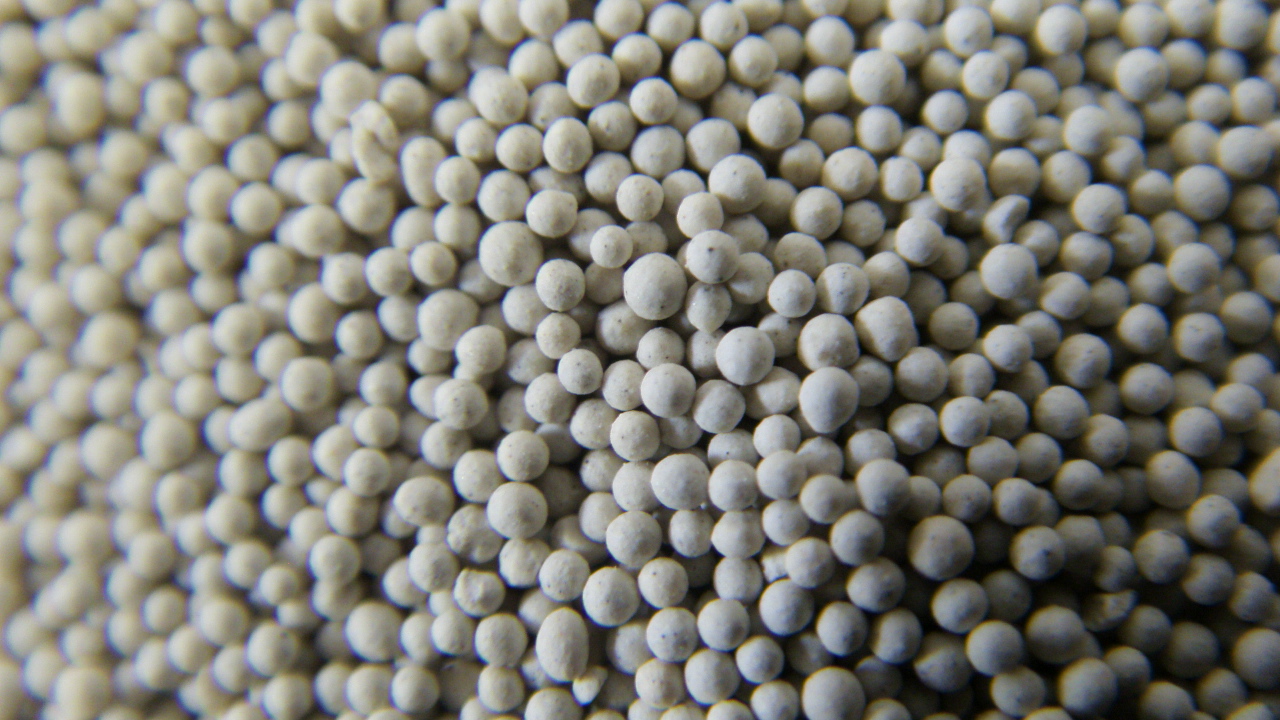

In recent years, the rise of synthetic sands has added a new dimension of control over the casting process. Often composed of alumino-silicates, synthetic sands promise repeatability and detail not possible with natural sands. Their engineered properties allow for precise adjustments in thermal behavior and grain composition, optimizing them for particular alloys and intricate designs. This customization leads to reduced scrap rates and rework, underscoring a focus on expertise and efficiency valued by quality-conscious manufacturers. Known for its ecological footprint, green sand remains one of the most versatile options. This moist mixture of sand, clay, and water derives its name from the moisture content rather than its color. It is particularly favored for its reusability and ease of handling during the molding process. As sustainability becomes a non-negotiable aspect of the production process, green sand satisfies both economic and environmental criteria, enabling industries to maintain high standards of accountability and social responsibility. Zircon sand excels in situations where the highest resistance to metal penetration and reaction is necessary. Its high density and lack of porosity give it a unique position in casting high-value components like turbine blades or intricate jewelry pieces. Investing in zircon speaks to a commitment to supreme quality and precision, where cost is balanced with the trust placed in the finished product's integrity. The selection of sand types profoundly impacts the casting process's outcome, shaping not just the physical properties of the product but also reflecting a company's ethos. Through prudent selection, firms demonstrate their commitment to safety, sustainability, and innovation. As they navigate the evolving expectations of modern consumers and regulators, their authoritative investment in material science and technology serves as a testament to their expertise and reliability. Post time:মার্চ . 03, 2025 12:28

Next:Ceramic casting sand for sand 3d printing