The History of Sand Casting An Enduring Legacy in Metalworking

Sand casting, one of the oldest methods of metalworking, has shaped the industrial landscape throughout history. This process involves creating a mold from a mixture of sand and a binding agent, into which molten metal is poured and subsequently solidified. From ancient civilizations to modern manufacturing, sand casting has demonstrated its versatility and enduring relevance.

The roots of sand casting can be traced back over 5,000 years to ancient civilizations such as the Egyptians and Chinese, who employed primitive techniques to create metal objects. Archaeological evidence indicates that the Egyptians utilized sand casting to produce bronze tools and weapons. The process allowed artisans to replicate intricate designs and shapes, which was a significant advancement from previous metal working methods. Similarly, the Chinese are credited with developing more sophisticated bronze casting techniques, including sand casting, during the Shang Dynasty (1600-1046 B.C.), evidence of which can be seen in their exquisite ritual vessels and ornaments.

The History of Sand Casting An Enduring Legacy in Metalworking

During the Middle Ages, the development of the foundry industry marked a significant shift in sand casting techniques. The introduction of new binding materials, such as clay and water, improved the strength and durability of molds. This innovation allowed for more extensive production runs and the creation of larger items, including bell, cannon, and church steeples. The demand for such castings surged, particularly as Europe entered the age of exploration and expansion, requiring various metal goods.

history of sand casting

The Industrial Revolution in the 18th and 19th centuries heralded a new era for sand casting. Mechanization and the advent of iron foundries transformed manufacturing. The introduction of sand casting into assembly line processes made mass production possible, drastically reducing costs and increasing output. This period saw the rise of standardized parts, which paved the way for modern engineering and manufacturing techniques.

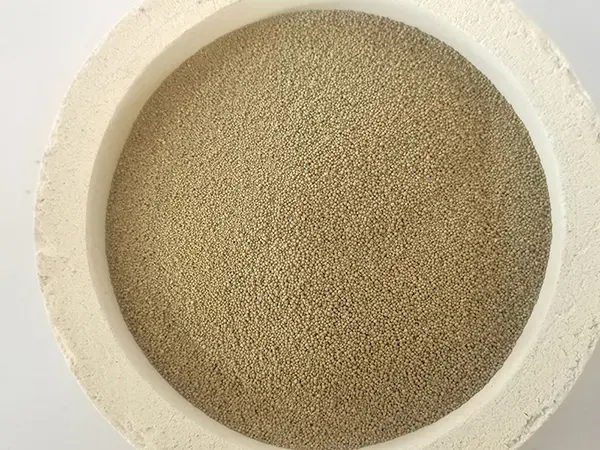

In the 20th century, further innovations enhanced the sand casting process. The introduction of silica sand provided a more uniform and high-quality mold material, leading to improved casting results. Advancements in technology allowed for better control of the pouring and cooling processes, reducing defects and increasing the precision of cast components. The application of sand casting expanded into various industries, including automotive, aerospace, and construction, where robust and reliable metal components are essential.

Today, while modern manufacturing techniques such as injection molding and 3D printing have emerged, sand casting remains a crucial method in many sectors. Its ability to produce large, complex shapes with various metals makes it irreplaceable for specific applications. Moreover, the process is adaptable, allowing manufacturers to tailor molds for unique needs.

Additionally, the rise of sustainable practices in metalworking has renewed interest in traditional techniques like sand casting. The use of reusable sand molds and environmentally friendly binders is becoming more prevalent, aligning with contemporary demands for green manufacturing solutions.

In conclusion, the history of sand casting is a testament to human ingenuity and adaptability. From ancient artisans to modern manufacturers, this time-honored method has evolved, meeting the changing demands of society while maintaining its core principles. As we move into the future, sand casting is likely to continue playing a vital role in the world of metalworking, bridging the gap between tradition and innovation.

Post time:ডিসে. . 18, 2024 11:25

Next:sanding machine 3d print