Understanding Sand Casting Tolerances

Sand casting is a widely used manufacturing process that involves creating metal parts by pouring molten metal into a cavity formed by a mold made from sand. This technique is popular due to its versatility, cost-effectiveness, and ability to produce complex shapes. However, one of the critical aspects of sand casting that impacts the quality of the final product is the tolerance levels that can be achieved during the process.

What are Tolerances in Sand Casting?

Tolerances in sand casting refer to the permissible limits of variation in a physical dimension or measured value of a finished part. These measurements can include dimensions such as length, width, height, and other geometric features. Tolerances are crucial because they dictate how closely the casting must adhere to specified dimensions and how it will fit with other components in an assembly.

Factors Affecting Tolerances

Several factors can influence the tolerances achievable in sand casting, including

1. Mold Design The complexity of the mold can significantly affect tolerances. Intricate designs may require more precise molds, while simpler shapes may allow for broader tolerances.

2. Pattern Material The material used for the pattern (the model used to create the mold cavity) can impact the surface finish and the overall dimensional stability of the sand mold. Patterns made from more rigid materials can lead to tighter tolerances.

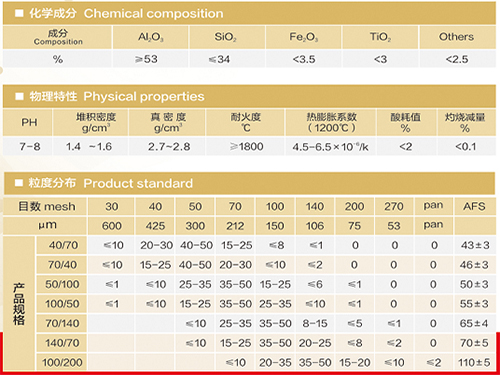

3. Sand Quality The type and quality of the sand mixture play a vital role in the mold's integrity. Fine sand with a high clay content can produce smoother surfaces and tighter tolerances but may also lead to issues such as lesser strength and dimensional stability.

4. Melting and Pouring Temperature The temperature at which the metal is melted and poured into the mold can affect shrinking rates. Metals typically expand when heated and contract when cooled; careful control of these temperatures can help achieve more consistent outcomes.

sand casting tolerances

5. Cooling Rate The cooling rate of the molten metal can also influence tolerances. Faster cooling can lead to increased shrinkage and warping, while controlled cooling can promote better dimensional stability.

Typical Tolerance Ranges

The tolerances for sand casting can vary widely depending on the specific application, but generally, the typical tolerance ranges are

- For rough castings, tolerances can be between ±1/8 inch. - For more sophisticated designs or higher-quality castings, tolerances might be around ±0.010 inches to ±0.030 inches.

Some high-precision applications may require tighter tolerances, but achieving these standards often involves additional processes, such as machining after casting.

Importance of Selecting the Right Tolerances

Selecting the appropriate tolerances is crucial because tighter tolerances often lead to increased production costs and longer lead times. Before manufacturing, it is essential to evaluate whether the intended use of the part warrants tighter specifications or if it can still function adequately with looser tolerances. Consulting with designers and engineers can help determine the best approach to balance cost and quality.

Conclusion

In summary, sand casting tolerances are a fundamental aspect of the casting process that affects the quality and functionality of the final product. Understanding the factors that influence tolerances can help manufacturers optimize their processes, reduce waste, and ensure that their cast products meet the required specifications. By striking the right balance between design complexity, pattern material, mold quality, and cooling techniques, manufacturers can achieve high-quality sand castings with satisfactory tolerances, contributing to the overall success of their production efforts.

Post time:окт. . 22, 2024 10:12

Next:Applications of Sand Casting in Manufacturing Various Components and Products