How Do You Sand Resin?

Resin is a versatile material used in a variety of crafts, from jewelry making to woodworking and even in the manufacture of prototypes. Its durable and glossy finish makes it desirable for many applications, but sometimes the surface can be imperfect or require refinement. Sanding resin is an essential skill for any craftsman working with this medium. In this article, we’ll explore the best practices for sanding resin effectively.

Why Sand Resin?

Sanding is necessary for several reasons. After pouring resin, bubbles or imperfections can form on the surface, leading to an unsatisfactory appearance. Sanding can help smooth out these irregularities, creating a polished and professional-looking finish. Additionally, if you plan to apply additional layers of resin or paint, sanding can create a better surface for adhesion by providing texture for the materials to grip onto.

Tools and Materials Needed

Before starting the sanding process, ensure you have the right tools and materials at hand

. Here’s what you’ll need1. Sandpaper Use a range of grits, typically starting from 60 or 80 for coarse sanding and moving up to 400 or higher for finer finishes. 2. Sanding Block or Orbital Sander For larger areas, an orbital sander can save time and effort. For detailed work, a sanding block will give you more control. 3. Water Wet sanding helps to reduce dust and prevents the resin from overheating and clogging the sandpaper. 4. Dust Mask and Safety Goggles Always prioritize your safety by wearing a dust mask to avoid inhaling particles and safety goggles to protect your eyes.

Step-by-Step Guide to Sanding Resin

1. Preparation Ensure your resin piece has fully cured according to the manufacturer’s instructions. This may take anywhere from a few hours to several days, depending on the type of resin used.

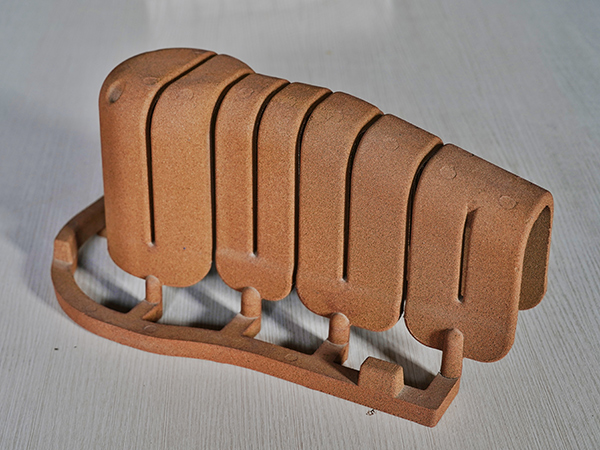

how do you sand resin

2. Initial Sanding Begin with a coarse grit sandpaper (60-80 grit). Sand the surface to remove any imperfections and smooth out the texture. If using an orbital sander, keep it moving to avoid creating flat spots. If sanding by hand, use circular motions and be consistent in pressure.

3. Check for Smoothness After the initial sanding, wipe the surface with a damp cloth to remove dust and debris. Check for smoothness and identify any areas that might need additional sanding.

4. Progressing to Finer Grits Gradually move to finer grits (120, 220, and finally 400 or higher). Each step should reduce the scratches left by the coarser grits. Use wet sanding at this stage, as it minimizes dust and heat—both of which can damage resin.

5. Polishing Once you reach a smooth finish with fine-grit sandpaper, consider polishing the resin. You can use a polishing compound and a soft cloth or a buffing wheel attached to a drill for a glossy finish. This step can enhance the overall appearance of your piece significantly.

6. Cleaning Up After sanding and polishing, thoroughly clean your workspace. The fine resin dust can be harmful if inhaled, and cleanup will prepare you for your next project.

Additional Tips

- Don’t Rush Take your time. Quick sanding can lead to uneven surfaces or even damage the resin piece. - Experiment with Techniques Depending on the look you want to achieve, consider experimenting with different sanding techniques, like using a random-orbit sander versus hand sanding. - Wear Protective Equipment Always prioritize safety. Beyond just a dust mask and goggles, consider gloves if you're handling resin regularly.

Conclusion

Sanding resin is a critical step in achieving a pristine finish in your projects. By using the right tools and following a methodical process, you can enhance the appearance of your resin pieces significantly. As with any craft, practice makes perfect, so don’t hesitate to experiment and refine your technique over time. Happy crafting!

Post time:дек. . 03, 2024 22:34

Next:sand casting china