Understanding Resin Coated Frac Sand A Key Component in Hydraulic Fracturing

In recent years, the oil and gas industry has witnessed significant advancements in extraction techniques, one of which is hydraulic fracturing or fracking. A crucial material that enhances the efficiency of this method is resin-coated frac sand. This article explores what resin-coated frac sand is, its benefits, and its role in modern fracking operations.

What is Resin Coated Frac Sand?

Resin-coated frac sand is a specialized type of sand that has been treated with a resin binder. This process involves applying a polymer resin to high-quality silica sand, significantly improving its properties. The primary purpose of this treatment is to enhance the performance of the sand in the fracking process, where maintaining structural integrity and conductivity in a fractured reservoir is essential.

Unlike traditional frac sand, which can be susceptible to degradation under high pressures and temperatures, resin-coated sand provides added strength and durability. The resin coating helps to reduce fines generation (the production of small particles during the fracking process) that can block the flow of oil and gas.

Benefits of Resin Coated Frac Sand

1. Increased Strength and Durability The resin coating significantly enhances the compressive strength of the sand particles, allowing it to withstand harsh conditions during the hydraulic fracturing process. This durability ensures that the sand maintains its shape and conductivity, allowing for better fluid movement in the reservoir.

2. Reduced Fines Generation One of the primary challenges in fracking is the generation of fine particles that can clog the fractures created in the rock formations. Resin-coated frac sand minimizes this issue, leading to improved flow rates and better overall production efficiency.

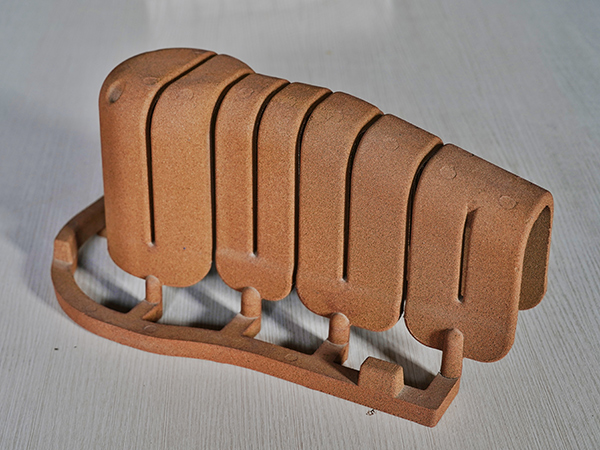

resin coated frac sand

3. Enhanced Conductivity The resin coating does not only strengthen the sand but also improves its conductivity. This is crucial for the effective flow of oil and gas through the fractures, ensuring maximum recovery from the well.

4. Cost-Effective Solution Although the initial investment in resin-coated frac sand may be higher than traditional sand, the long-term benefits outweigh these costs. The increased efficiency and reduced operational challenges often lead to higher production rates and lower overall costs for operators.

5. Environmental Considerations The use of resin-coated sand may also have environmental benefits. With reduced fines, there is less chance of creating waste that could affect surrounding water sources and ecosystems.

The Role of Resin Coated Frac Sand in Hydraulic Fracturing

Hydraulic fracturing involves injecting a mixture of water, proppants (like sand), and chemicals into the well at high pressures to create fractures in the rock formations. These fractures enable the extraction of oil and gas resources that would otherwise be inaccessible. Resin-coated frac sand plays a crucial role in this operation by serving as a proppant that holds the fractures open, allowing hydrocarbons to flow more freely.

As the industry continues to evolve, the demand for high-quality proppants will remain significant. The use of resin-coated frac sand is gaining traction due to its performance advantages and ability to optimize extraction operations.

Conclusion

In conclusion, resin-coated frac sand has become an indispensable component of the hydraulic fracturing process. Its enhanced strength, reduced fines generation, and improved conductivity make it a preferred choice for oil and gas operators seeking to maximize their production potential. As the industry looks towards more efficient and environmentally friendly practices, the role of resin-coated frac sand will likely continue to expand, ensuring that the extraction of natural resources remains effective and sustainable.

Post time:авг. . 14, 2024 09:36

Next:Attractive Options for Purchasing Gold and Sand Varieties for Your Investment Needs