Lost Foam Casting An Innovative Approach to Metal Casting

Lost foam casting (LFC) represents a fascinating advancement in the metal casting industry, combining traditional techniques with modern technological insights. This process is particularly valued for its ability to create complex shapes and intricate designs with high precision. Unlike conventional sand casting methods, where patterns are made of metal or wood, lost foam casting utilizes a soluble foam pattern that is vaporized during the casting process.

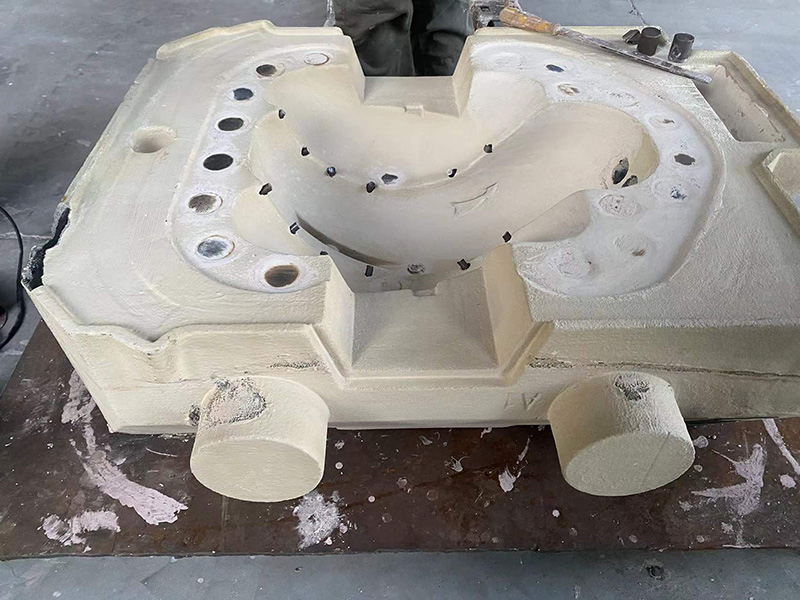

The lost foam casting process begins with the creation of a foam pattern, typically made from polystyrene. These patterns can be shaped into intricate geometries that would be exceedingly difficult or costly to achieve with traditional methods. The foam patterns are then coated with a special refractory material, creating a thin shell. Once the coating has set, the coated foam is placed in a mold. The next step is the pouring of molten metal into the mold. When the metal fills the mold, it simultaneously heats up and vaporizes the foam pattern, creating a hollow space in the shape of the original pattern. This unique aspect of lost foam casting allows for remarkable flexibility in design, enabling the production of complex shapes without the need for additional tooling.

lost foam casting

One of the key benefits of lost foam casting is its efficiency. It significantly reduces material waste since there is no need for traditional cores or excessive machining. Additionally, the process can yield refined surface finishes, thus minimizing the need for post-casting machining. This aspect is particularly appealing in sectors such as automotive and aerospace, where weight reduction is a critical consideration. The precision achievable through LFC is particularly advantageous for creating components with tight tolerances.

Moreover, lost foam casting is versatile in terms of the materials that can be used. It is applicable to a wide range of metals, including aluminum, iron, and steel, making it a go-to solution for manufacturers seeking to produce high-quality components across various industries. The economic advantage, coupled with the ability to create lightweight parts, continues to propel the adoption of lost foam casting in modern manufacturing.

In conclusion, lost foam casting is a pioneering method that exemplifies innovation in the metal casting realm. Its ability to deliver complex designs with high precision while reducing waste makes it a desirable choice for manufacturers aiming for efficiency and cost-effectiveness. As industries evolve and the demand for precise, lightweight components grows, lost foam casting is poised to play a critical role in the future of manufacturing, exemplifying the intersection of technology and craftsmanship.

Post time:Верас . 28, 2024 20:20

Next:Creating High-Quality Foundry Sand for Metal Casting Applications