The Importance of Foundry Sand Reuse in Sustainable Manufacturing

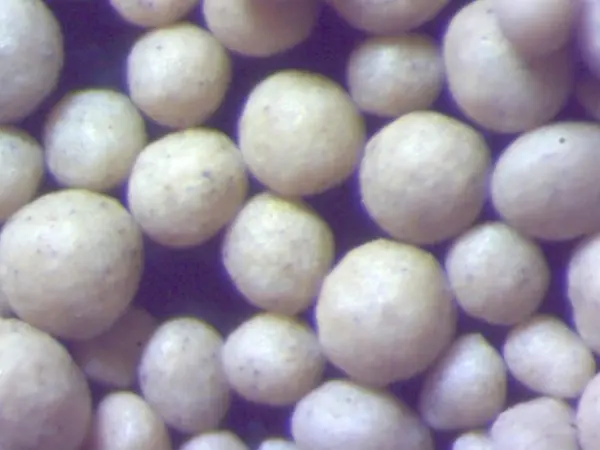

Foundry sand, a high-quality silica sand, is a crucial material in the metal casting industry. Traditionally, it is used to create molds and cores for shaping molten metal. However, the production and disposal of foundry sand generate significant environmental impacts and economic costs. Therefore, the reuse of foundry sand is increasingly being recognized as a vital strategy for promoting sustainability within the manufacturing sector.

One of the primary benefits of reusing foundry sand is the reduction of waste. In the United States alone, foundries generate millions of tons of spent sand annually, much of which ends up in landfills. This not only contributes to the depletion of landfill space but also poses environmental hazards, including soil and water contamination. By reintroducing used sand into the production process, foundries can significantly decrease their waste output. Moreover, reusing foundry sand aligns with the principles of circular economy, where materials are kept in use for as long as possible, thus minimizing the need for virgin resources.

In addition to waste reduction, foundry sand reuse offers substantial cost savings for manufacturers. Purchasing new sand can be expensive. By recycling and reusing foundry sand, companies can lower their material procurement costs and improve their bottom line. This is particularly important in a competitive industry where margins can be tight. Furthermore, the reuse of sand may also lead to reduced transportation costs and lower carbon emissions associated with the shipping of virgin materials.

foundry sand reuse

Another advantage of foundry sand reuse is its potential to enhance the properties of composite materials. Used foundry sand contains beneficial characteristics that can improve the performance of other materials. For instance, when incorporated into concrete, foundry sand can enhance compressive strength and reduce permeability, making it a valuable substitute for traditional aggregates. This not only adds value to the sand itself but also opens new markets for foundry by-products, fostering innovation in product development.

Despite the evident benefits of foundry sand reuse, there are challenges that must be addressed. First, the consistency and quality of reused sand can vary, affecting its suitability for certain applications. Foundries must implement rigorous quality control measures and establish proper processing techniques to ensure that reused sand meets industry standards. Second, there are regulatory hurdles that may hinder the reuse of spent foundry sand. Policymakers must create supportive frameworks and guidelines that facilitate recycling while ensuring environmental safety.

Education and collaboration among stakeholders is also critical for promoting foundry sand reuse. Foundries, manufacturers, researchers, and policymakers should work together to share best practices, research findings, and innovative technologies. Workshops, training programs, and collaborative projects can raise awareness of the benefits of foundry sand reuse while developing practical solutions to existing challenges.

In conclusion, the reuse of foundry sand represents a significant opportunity for sustainable manufacturing. By reducing waste, lowering costs, enhancing material properties, and fostering collaboration, the metal casting industry can not only improve its environmental footprint but also create economic opportunities. As the global conversation around sustainability continues to grow, foundry sand reuse can serve as a model for other industries seeking to achieve similar goals. Embracing this practice can lead to a more circular economy, allowing for the efficient use of resources and a cleaner, more sustainable future.

Post time:снеж . 13, 2024 06:30

Next:molding sand for metal casting