The foundry sand casting process is a fundamental manufacturing technique widely used for producing intricate metal parts. This process harnesses the unique properties of sand to create molds that can withstand the extreme temperatures required for metal casting. Understanding the steps and intricacies of sand casting can provide insight into its widespread adoption across various industries, including automotive, aerospace, and machinery.

The foundry sand casting process is a fundamental manufacturing technique widely used for producing intricate metal parts. This process harnesses the unique properties of sand to create molds that can withstand the extreme temperatures required for metal casting. Understanding the steps and intricacies of sand casting can provide insight into its widespread adoption across various industries, including automotive, aerospace, and machinery.

After the pattern is removed, the two halves of the mold are assembled, and gating systems—channels that guide the molten metal into the mold cavity—are integrated. The next step involves heating the desired metal until it reaches a molten state, which is usually achieved through furnaces that can reach several thousand degrees Celsius. Once the metal is adequately melted, it is poured into the mold through the gating system.

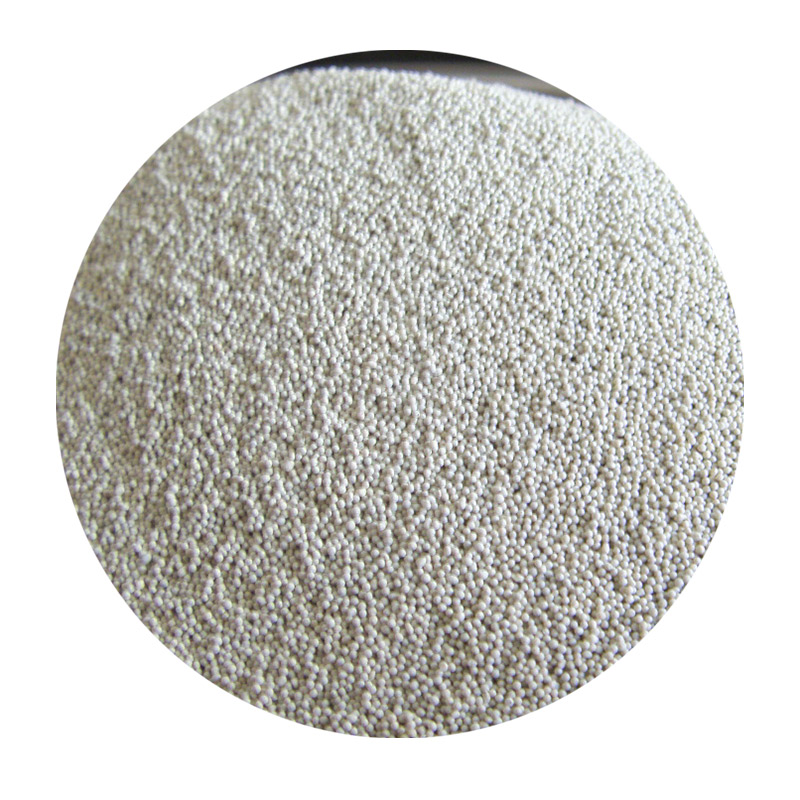

foundry sand casting process

Cooling is a critical phase of the sand casting process. As the metal solidifies, it takes on the shape of the mold. This process can take anywhere from a few minutes to several hours, depending on the thickness of the casting and the type of metal used. After cooling, the mold is broken away, revealing the cast part. Finishing operations, such as grinding and machining, may follow to achieve the desired surface finish and tolerances.

One of the key advantages of the sand casting process is its versatility. It can accommodate a wide variety of metals, including aluminum, iron, and bronze, and is suitable for both small and large parts. Moreover, it allows for complex geometries that are often challenging to achieve with other manufacturing methods.

In conclusion, the foundry sand casting process remains a vital method in modern manufacturing, offering both flexibility and efficiency in producing high-quality metal components. Its relevance continues to grow as industries seek innovative solutions for complex manufacturing challenges.

Post time:Ліст . 02, 2024 08:35

Next:what is gold sand