- Introduction to Dry Sand Casting and Industrial Significance

- Step-by-Step Breakdown of Dry Sand Casting Process

- Technical Advantages vs. Alternative Manufacturing Methods

- Performance Metrics: Data Comparison Across Casting Technologies

- Manufacturer Evaluation Criteria for Dry Sand Casting

- Customization Capabilities for Specialized Applications

- Future Outlook: Sustainable Manufacturing Integration

(dry sand casting)

Understanding Dry Sand Casting for Industrial Applications

Dry sand casting stands as a foundational metalworking technique where sand molds baked at 200-350°C create durable, high-integrity cavities for molten metal. Distinct from green sand casting using moist binders, this process utilizes thermally cured molds achieving dimensional stability within ±2.0 mm per meter. Industrial sectors requiring large components – particularly automotive (42%), heavy machinery (23%), and energy infrastructure (18%) – leverage its capacity for castings weighing 50 kg to 40 tons. The method offers production flexibility unattainable with rigid mold systems, accommodating design alterations 5x faster than permanent mold alternatives while maintaining tensile strengths reaching 220 MPa in ferrous alloys.

The Core Mechanism Behind Mold Creation

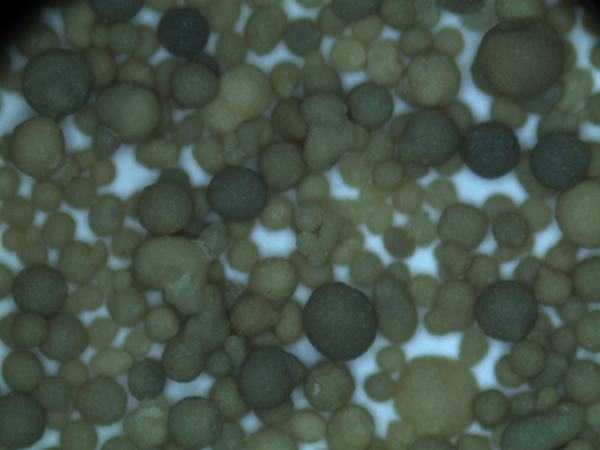

Dry sand casting initiates with pattern assembly on match plates, where specialized sands mixed with 3-7% thermosetting resins compact around tooling under 25-35 psi pressure. Molds undergo precision curing in convection ovens for 12-48 hours, driving polymerization reactions that establish cross-linked bonds. This baking phase eliminates moisture content below 0.3%, enabling vent permeability 40% higher than green sand counterparts to prevent gas defects. Crucially, mold rigidity controls solidification shrinkage, reducing cooling stresses by approximately 15-30% compared to faster-chilling die cast parts. Foundries utilize proprietary refractory coatings (zircon/zirconia formulations dominate 68% of applications) applied at 15-40μm thickness before casting, preventing metal penetration while achieving surface finishes averaging 250-500 μin Ra.

Technical Superiority in Metallurgical Outcomes

Material versatility defines dry sand casting

's superiority, handling metals with pouring temperatures exceeding 1650°C – including chromium alloys impossible for die casting. Component porosity remains below 0.9% volume, substantially lower than 1.8-2.5% typifying pressure-die-cast aluminum. The gradual solidification refines grain structures, increasing ductility by 20-40% over equivalent die-cast parts. Machining data validates these metallurgical advantages: machining forces in dry sand castings average 12% lower than die cast equivalents due to uniform microstructure. Production economics reveal equally compelling differentiation; mold tooling costs typically range $6,000-$45,000, undercutting die casting tooling by 60-80% for large components. Additionally, low-volume production runs (under 1,000 units) deliver 30-50% cost savings by avoiding capital-intensive dies.

Quantitative Comparison Across Manufacturing Methods

| Parameter | Dry Sand Casting | Die Casting | Green Sand Casting |

|---|---|---|---|

| Dimensional Tolerance | ±0.50-1.25 mm | ±0.12-0.25 mm | ±0.75-1.75 mm |

| Surface Finish (Ra) | 3.2-12.5 μm | 0.8-3.2 μm | 12.5-25 μm |

| Max Weight Capacity | 40,000 kg | 35 kg | 20,000 kg |

| Wall Thickness Range | 4-300 mm | 0.6-12.7 mm | 5-150 mm |

| Lead Time Modification | 48-72 hours | 2-4 weeks | 24-48 hours |

| Tooling Investment | $6K-$45K | $25K-$300K | $3K-$20K |

Manufacturing Partner Selection Protocol

Four technical capabilities dictate foundry proficiency: binder system expertise (phenolic urethane vs. sodium silicate advantages), thermal management systems regulating mold preheat temperatures within ±15°C, and metallurgical analysis infrastructure conducting spectrographic verification per ASTM E1251. Component traceability requirements mandate foundries implement DPM (Direct Part Marking) systems with 99.98% scan rates in tier-1 automotive applications. Production scalability varies significantly – specialized European producers like Vesuvius Group handle volumes exceeding 1,200 metric tons monthly, while American counterparts including Grede Holdings optimize batches below 500 tons with rapid pattern-change capabilities (under 12 minutes). Crucially, environmental compliance distinguishes leaders, where advanced thermal oxidizers reduce VOC emissions to 8-12 g/kg of sand – 60% below regulatory thresholds.

Industry-Specific Engineering Solutions

Turbine housing manufacturers harness the dry sand casting process to create complex geometries with 16% wall thickness variation, integrating cooling channels impossible through machining. Naval propulsion systems showcase its capacity for nickel-aluminum-bronze alloys with controlled copper precipitation – achieving 40% elongation in seawater environments. Material innovations include zircon-reinforced molds supporting titanium pours exceeding 3,200°F without reactivity. For high-wear applications, foundries implement differential cooling techniques generating secondary hardness phases at bearing surfaces. One wind energy project demonstrated this capability: incremental surface chilling increased gearbox housing surface hardness to 375 HB while maintaining 180 HB core ductility. Emerging partnerships combine sand cores with additive manufacturing, merging conformal cooling channels reducing machining by 85% in hydraulic valve bodies.

Dry Sand Casting: Sustainable Production Integration

Modern foundries now reclaim 94-97% of sand through mechanical/thermal regeneration systems, reducing virgin sand consumption below 4.5 tons per 100 tons of castings. Lifecycle analyses confirm carbon emissions reductions of 19-27% versus high-pressure die casting for components exceeding 60kg – primarily attributable to lower tooling energy intensity. Research consortiums currently develop bio-derived binders achieving comparable mold strength from lignin polymers, eliminating formaldehyde emissions during baking. The dry sand casting process maintains critical advantages for renewable infrastructure projects where turbine bases require single-piece integrity – evidenced by Alstom's adoption for 5MW generator frames requiring dimensional stability across 8-meter spans. Global foundry modernization programs project 4.5% CAGR through 2032, increasingly leveraging process automation for robotic mold handling that reduces dimensional variation by an additional 35%.

(dry sand casting)

FAQS on dry sand casting

Q: What is the dry sand casting process?

A: Dry sand casting involves using sand molds bonded with clay and baked to remove moisture. This creates rigid molds for casting metals, ideal for large or complex parts. It avoids the need for wet sand binders, improving dimensional stability.

Q: How does dry sand casting differ from regular sand casting?

A: Dry sand casting uses oven-dried molds for higher strength and precision, while traditional sand casting uses moist sand. Dry sand molds reduce gas-related defects and handle higher temperatures. However, they take longer to prepare due to baking.

Q: What are the key differences between sand casting and die casting?

A: Sand casting uses expendable sand molds for lower-cost, larger parts, while die casting employs reusable metal molds for high-volume, detailed components. Sand casting suits alloys like steel, whereas die casting works best with aluminum or zinc. Die casting offers smoother finishes but higher upfront costs.

Q: What are the advantages of dry sand casting?

A: Dry sand casting provides better mold rigidity and reduced porosity compared to wet sand methods. It supports intricate designs and large-scale production. The process also minimizes moisture-related defects like blowholes.

Q: When is dry sand casting preferred over die casting?

A: Dry sand casting is chosen for large, heavy, or low-volume parts requiring cost-effective molds. Die casting is better for mass-producing small, precise components. Dry sand casting also accommodates metals with higher melting points, like iron or steel.

Next:Affordable Sand Casting Price Quality Casting Sand & 3D Printer Deals