The Art and Science of Sanding Resin A Comprehensive Guide

Sanding resin is a crucial step in the finishing process of resin-based projects. Whether you're creating stunning art pieces, functional items, or automotive components, understanding the intricacies of sanding resin can significantly impact the final look and feel of your creation. This article aims to delve into the importance of sanding resin, the techniques involved, and tips for achieving a flawless finish.

Understanding Resin

Resin, particularly epoxy resin, is a synthetic compound widely used for its versatility and durability. It is popular among artisans and hobbyists for crafting items like jewelry, coasters, and tabletops. Once the resin has been cured, it forms a hard, glass-like surface that can be sanded, polished, and finished to achieve a desired aesthetic.

The Importance of Sanding

Sanding resin is essential for several reasons

1. Surface Preparation It removes any imperfections or irregularities present in the cured resin. Air bubbles, dust particles, or unwanted textures can detract from the overall appearance, making sanding a necessary step for achieving a smooth surface.

2. Enhancing Adhesion If you plan to paint, coat, or apply additional layers to your resin piece, sanding can create a rougher surface that enhances adhesion. This is crucial for ensuring that subsequent layers adhere properly and do not peel or chip away.

3. Aesthetic Appeal A well-sanded and polished resin piece reveals the beauty of the materials embedded within. Whether it’s glitter, pigments, or natural elements, sanding helps to highlight these features, creating a visually striking effect.

Sanding Techniques

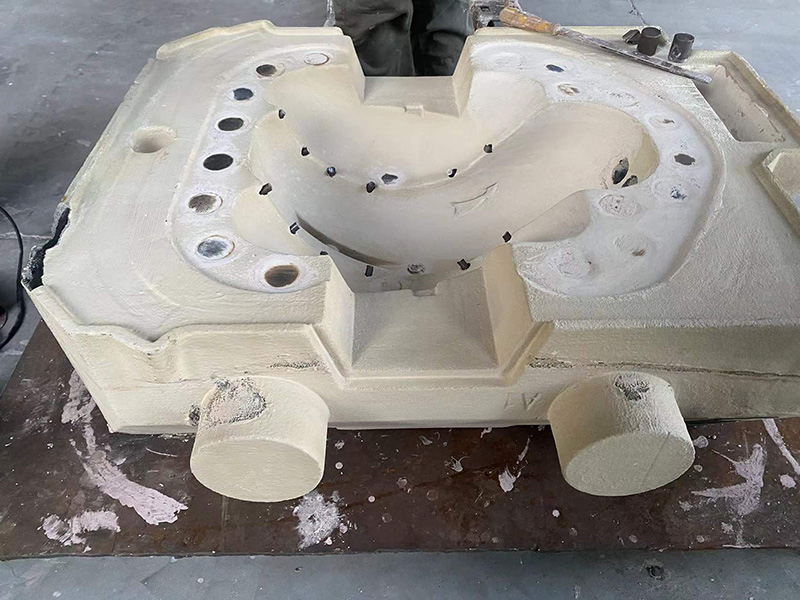

sanding resin

To achieve the best results when sanding resin, it’s essential to follow a methodical approach

1. Choose the Right Tools Start with a selection of sandpaper of varying grits. Generally, you'll want to begin with a coarser grit (around 80-120) to remove larger imperfections and gradually move to finer grits (up to 2000) for smoothing the surface.

2. Wet Sanding vs. Dry Sanding Wet sanding, where water is used to lubricate the surface, is often recommended for resin. It minimizes dust and helps to prevent the sandpaper from clogging. Additionally, wet sanding can provide a smoother finish by reducing friction and heat.

3. Sanding Technique Use a random orbital sander or a sanding block for larger flat surfaces. For intricate designs or edges, hand sanding might be necessary. Sand in circular motions and ensure even pressure to avoid creating uneven spots.

4. Progress Gradually Start with a coarse grit and gradually move to finer grits, allowing the surface to improve with each pass. Skipping grits can result in a less smooth finish, as larger scratches left from coarser grits may remain visible.

5. Cleaning Between Grids It’s crucial to clean the surface after using each grit. This can be done with a microfiber cloth or a soft brush to remove dust and residue, allowing for better visibility of the surface quality.

Finishing Touches

Once you've completed the sanding process, the final step is polishing. This can be done with a polishing compound and a buffing wheel or cloth. Polishing not only enhances clarity and shine but also helps to protect the resin from future scratches and UV damage.

In conclusion, sanding resin is a vital skill for anyone working with epoxy or other types of resin materials. By following the right techniques and allowing for a methodical approach, you can achieve a professional-looking finish that enhances the beauty and durability of your creations. Whether you're a hobbyist or a professional, mastering the art of sanding resin will undoubtedly elevate your projects to new heights.

Post time:Noy . 09, 2024 00:12

Next:Molding Sand Requirements and Types for Effective Metal Casting Processes