Sand Sintering A Comprehensive Overview

Sand sintering is a vital process in various fields, including material science and engineering, particularly in the fabrication of advanced materials. This process involves the transformation of sand, a granular material, into a solid mass through the application of heat and pressure, without reaching the point of melting. Sintering is primarily used to create dense, durable materials suitable for various applications, including construction, ceramics, and even microelectronics.

The Process of Sand Sintering

The sintering process begins with the selection of high-quality sand, generally quartz-based, due to its unique properties such as high melting point and excellent thermal stability. The sand particles are typically mixed with a binder to enhance the mechanical properties of the final product. The binder can be organic or inorganic, depending on the desired characteristics of the sintered material.

Once the mixture is prepared, it undergoes shaping, where it is formed into the desired geometry, often using methods such as pressing or extrusion. This initial shaping is crucial, as it defines the final dimensions and structure of the sintered product.

The next phase is the heating process, where the shaped sand is subjected to controlled temperatures in a furnace. The heat facilitates particle diffusion, causing them to bond together at their contact points. This bonding is critical as it enhances the strength and integrity of the final product.

The sintering temperature and time are critical parameters that influence the characteristics of the final product. Higher temperatures generally lead to improved densification and strength but can also lead to issues such as grain growth, which may reduce the material's overall stability. Therefore, careful optimization of these parameters is essential.

After the sintering process, the product is cooled down, and it is often subjected to post-sintering treatments to further enhance its properties. These treatments may include additional annealing, surface finishing, or coating processes, depending on the application of the sintered material.

Applications of Sand Sintering

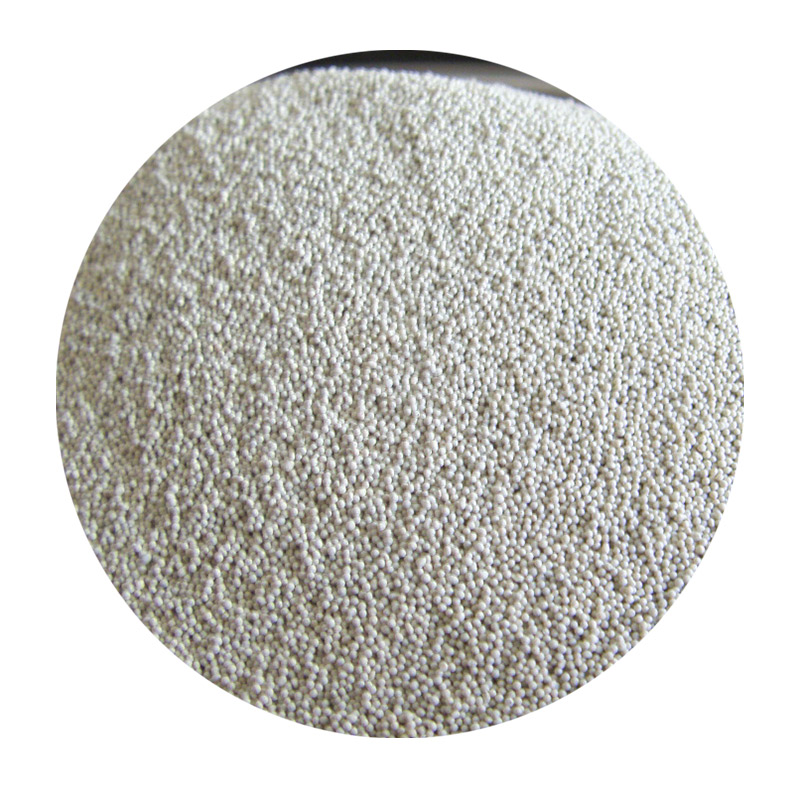

sand sintering

Sand sintering has a broad range of applications across various industries. In construction, for instance, sintered sand can be used to create durable components like bricks and tiles, which offer excellent resistance to environmental factors such as moisture and temperature fluctuations. The use of sintered materials in construction is increasingly popular due to their sustainability characteristics, as they often utilize recycled materials and reduce waste.

In the field of ceramics, sand sintering is employed to produce high-performance products like dental ceramics, where precision and strength are paramount. The ability to control the microstructure during sintering allows for the creation of materials with tailored properties.

Moreover, the electronics industry is beginning to explore the benefits of sand sintering in the production of various components

. The process can be utilized to create substrates for electronic circuits, where high thermal and electrical conductivity is required. Sand-sintered materials can also be incorporated into the production of sensors and other critical electronic components.Advantages and Challenges

The primary advantages of sand sintering include the ability to produce complex geometries and the versatility of materials that can be used in the process. Furthermore, the reduction of material waste and the potential for recycling make it an environmentally friendly manufacturing method.

However, sand sintering is not without its challenges. The need for precise control over process parameters to achieve the desired material properties can complicate production. Additionally, the initial costs of setup and technology can be high, which may deter smaller manufacturers from adopting this method.

Future Prospects

The future of sand sintering looks promising with advancements in technology and materials science. Ongoing research aims to enhance the sintering process to produce even higher quality materials while minimizing energy consumption. Innovations such as 3D printing with sintered materials are also making waves, potentially revolutionizing the way components are designed and manufactured.

In conclusion, sand sintering is a significant process with extensive applications across various industries. Its ability to create durable, high-quality products makes it an essential technology in modern manufacturing. As research continues and new technologies emerge, the potential for sand sintering is vast, paving the way for even more innovative materials and applications in the future.

Post time:ديسمبر . 16, 2024 04:22

Next:Exploring Various Methods and Techniques in Sand Casting Processes