Sand Casting Companies An Overview of the Industry

Sand casting, also known as sand mold casting, is one of the oldest and most widely used metal casting processes in the manufacturing industry. This method involves creating molds from sand and using them to form metal objects. With its ability to produce complex shapes and withstand high temperatures, sand casting continues to be a vital technique in various applications, from engineering components to art pieces. This article provides an overview of sand casting companies, their processes, and the benefits of choosing this manufacturing method.

The Sand Casting Process

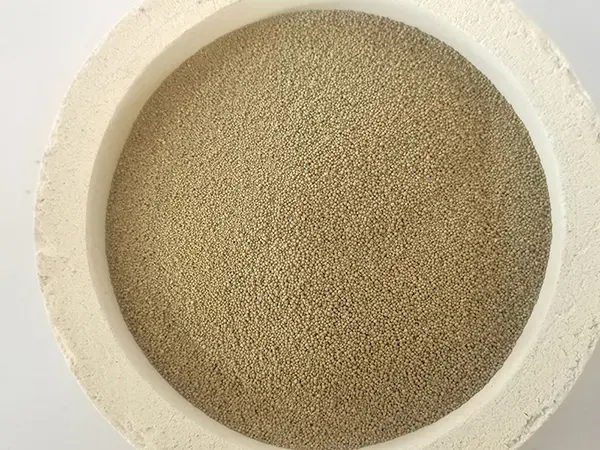

The sand casting process primarily involves several key steps. First, a pattern is created, usually made of metal or wood, which represents the final product's shape. This pattern is then used to create a sand mold. The mold is formed by mixing sand with a binder material and packing it around the pattern. Once the mold is adequately prepared, the pattern is removed, leaving a cavity that mirrors the desired object.

Next, molten metal is poured into the mold cavity. Once the metal cools and solidifies, the mold is broken away to reveal the cast object, which may require further processing, such as machining or finishing. The versatility of sand casting allows it to be used with various metals, including iron, aluminum, bronze, and magnesium, making it suitable for producing a wide range of products.

The Role of Sand Casting Companies

Sand casting companies play a crucial role in the manufacturing industry by providing expertise, facilities, and resources to produce high-quality castings. These companies often work across various sectors, including automotive, aerospace, construction, and art. By collaborating with clients to understand their specific needs, they can optimize the casting process to deliver tailored solutions.

One of the advantages of sand casting companies is their ability to handle both small and large production runs

. Many companies offer rapid prototyping services, allowing clients to obtain samples quickly and test designs before committing to larger quantities. This flexibility not only reduces lead times but also minimizes material waste, making the process more efficient.sand casting companies

Benefits of Choosing Sand Casting

There are several benefits to selecting sand casting for manufacturing needs. First and foremost, it is a cost-effective method for producing complex geometries. The use of sand molds allows for intricate designs that might be challenging or expensive to achieve with other casting methods.

Additionally, sand casting can accommodate a wide range of part sizes. Whether a client requires small components or large industrial parts, sand casting companies can adjust their molds and processes to meet these demands. Moreover, because sand is an abundant and readily available material, the overall production cost is often lower compared to other casting techniques, which may require specialized materials.

Environmentally Friendly Practices

Many sand casting companies are adopting environmentally friendly practices in their operations. This includes using recyclable sand and implementing waste reduction strategies. By improving the sustainability of the sand casting process, these companies contribute to a more environmentally responsible manufacturing landscape.

Conclusion

In conclusion, sand casting companies are integral to the manufacturing sector, providing essential services that allow for the production of intricate and high-quality metal parts. By leveraging the advantages of sand casting, these companies help businesses across various industries achieve their production goals efficiently and cost-effectively. With ongoing advancements in technology and sustainable practices, the future of sand casting looks promising, ensuring that it remains a preferred choice for manufacturers worldwide.

Post time:نوفمبر . 27, 2024 11:00

Next:Managing Contamination Issues in Foundry Sand for Optimal Casting Quality and Performance