The Art and Science of Sand Castings

Sand casting is a versatile and widely-used manufacturing process that dates back thousands of years. It involves creating a mold from a sand mixture to cast metal into desired shapes. This technique is not only one of the oldest but also remains relevant today in various industries, including automotive, aerospace, and machinery production.

The Art and Science of Sand Castings

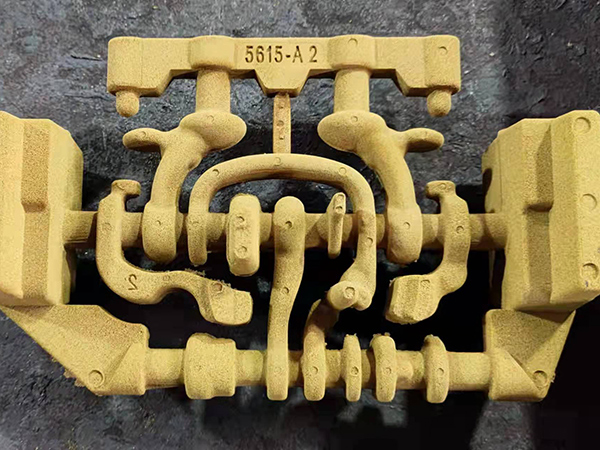

One of the significant advantages of sand casting is its ability to create complex shapes with intricate details. This makes it ideal for producing parts such as engine blocks, pump housings, and various components that require precision. Additionally, sand casting can accommodate large and heavy parts, making it suitable for industries that need robust and durable components.

sand castings

After the mold is formed, molten metal is poured into the cavity. This stage requires careful control of the temperature and pouring speed to prevent defects such as air pockets or incomplete filling. Once the metal cools and solidifies, the sand mold is broken away to reveal the cast metal part.

Another reason for the popularity of sand casting is its cost-effectiveness. The materials used for the molds are relatively inexpensive, and the process can be scaled up or down according to production needs. Sand molds can also be reused multiple times, further reducing waste and costs.

However, sand casting does have its drawbacks. The final surface finish of castings made from sand molds is often rough and may require additional machining processes to achieve the desired smoothness. Moreover, the dimensional accuracy may not be as high as other casting methods, such as die casting.

In conclusion, sand casting remains a fundamental method in metalworking due to its versatility and cost-effectiveness. Despite the advent of more advanced technologies, its ability to create complex and large-scale components ensures its continued relevance in modern manufacturing. As industries evolve, sand casting will likely adapt, integrating new technologies to enhance its capabilities and efficiency.

Post time:سبتمبر . 09, 2024 21:59

Next:Сандынг 3D друк