Understanding Sand Casting An Overview of the Process

Sand casting is one of the oldest and most versatile metal casting processes utilized in the manufacturing industry. This technique has been used for thousands of years to create everything from simple tools to complex machinery components. Understanding how sand casting works can provide insights into its advantages, its applications, and its significance in contemporary manufacturing processes.

What is Sand Casting?

Sand casting, also known as sand mold casting, involves creating a mold for metal objects using sand as the primary material. The process begins with preparing a pattern, which is a replica of the object to be cast, typically made from metal, plastic, or wood. The pattern is then used to form a mold cavity in a mixture of sand and a binding agent, usually clay or a resin. The mold is designed to allow molten metal to be poured into it, taking the shape of the desired object once cooled and solidified.

The Sand Casting Process

1. Pattern Creation The initial step in sand casting is creating a pattern of the object to be manufactured. The pattern must be slightly larger than the final product to account for the shrinkage that occurs during cooling.

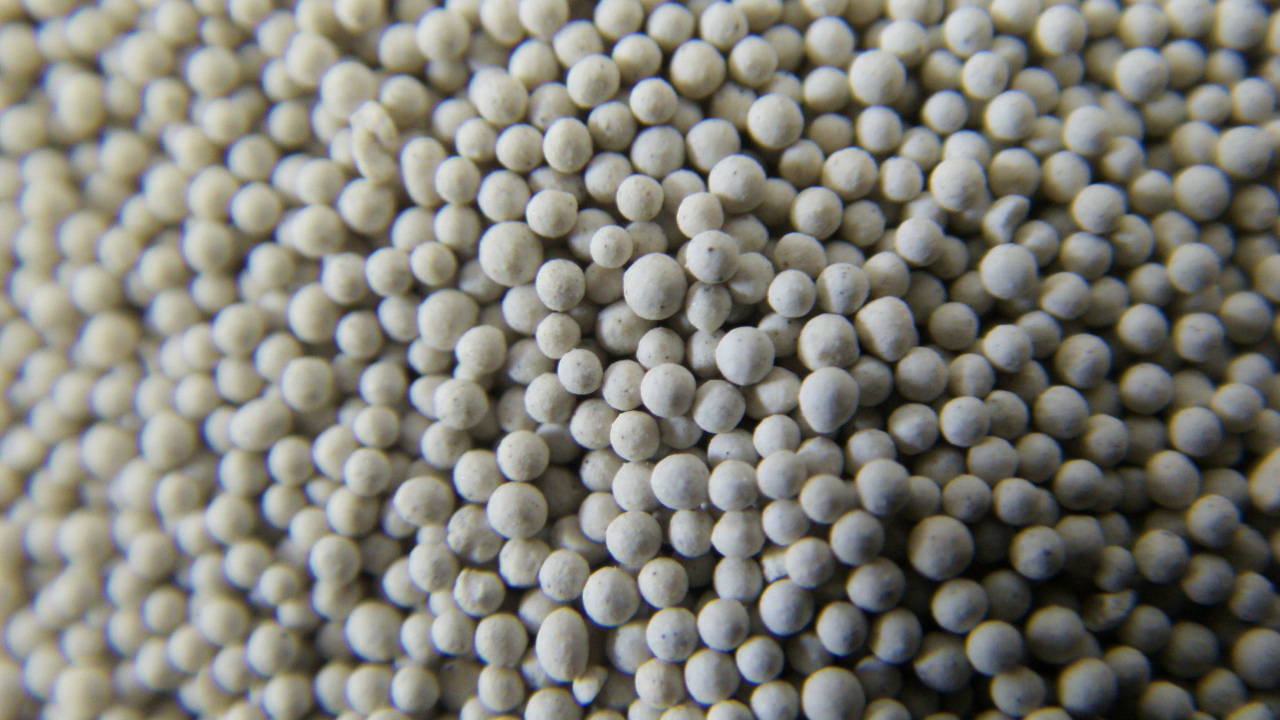

2. Mold Making The next step involves packing sand around the pattern. This is often done in two halves to create a mold cavity. The sand is mixed with a binder, which helps it hold its shape. Once the sand is tightly packed around the pattern, it is removed, leaving behind a hollow cavity that replicates the shape of the pattern.

3. Core Creation (if needed) For hollow sections or intricate designs, sand cores can be created and placed in the mold. These cores form the internal features of the casting and are also made of sand.

4. Pouring Once the mold is prepared, it is assembled, and molten metal is poured into the cavity. The temperature of the molten metal varies depending on the type of metal being used, but it typically ranges from 1,200°C to 1,600°C (2,200°F to 2,900°F).

5. Cooling After the metal has been poured, it needs to cool and solidify. The cooling time depends on the size of the casting and the type of metal. Once solidified, the mold is broken away to reveal the casting.

how does sand casting work

6. Finishing The final step involves cleaning the casting, which may include removing sand residues and any imperfections. This may involve machining, shot blasting, or other methods to achieve the desired surface finish and tolerances.

Advantages of Sand Casting

1. Versatility Sand casting can accommodate a wide range of shapes and sizes, from small components to large, complex parts. This makes it suitable for various industries, including automotive, aerospace, and art.

2. Cost-Effectiveness The materials used in sand casting, primarily sand, are inexpensive and readily available. Additionally, the process does not require expensive tooling for many applications, making it a viable option for small production runs.

3. Good Mechanical Properties Cast parts often have good mechanical properties, depending on the metal used, which can withstand considerable stress and strain.

4. Rapid Prototyping Sand casting enables fast production of prototypes, facilitating quicker design iterations and testing of new products.

Applications of Sand Casting

Sand casting is utilized in various applications, including the production of engine blocks, valve bodies, and many other automotive components. It is also commonly employed in creating intricate parts for aerospace structures and industrial equipment. Additionally, artists use sand casting to produce sculptures and various forms of decorative items.

Conclusion

In essence, sand casting is a time-tested and highly adaptable manufacturing process that continues to play a crucial role in modern industry. Its combination of flexibility, cost-effectiveness, and the ability to produce complex shapes makes it an essential technique in the production of metal components. As manufacturing technology advances, sand casting remains relevant, demonstrating the enduring value of this ancient method in today's diverse industrial landscape.

Post time:نوفمبر . 11, 2024 15:47

Next:sand casting manufacturer