Sanding 3D Prints The Key to a Smooth Finish

3D printing is a revolutionary technology that has transformed the way we create and manufacture objects. However, one common downside to many 3D printing methods, especially those using Fused Deposition Modeling (FDM), is the layer-by-layer finish that can result in a rough surface texture. To achieve a polished and professional look, sanding becomes an essential step in the post-processing phase of 3D prints.

The purpose of sanding 3D prints is to improve their surface finish and overall appearance. While 3D prints can be quite detailed, the layering effect often leaves visible ridges and imperfections. Sanding helps to smooth these out, resulting in a product that looks more refined and aesthetically pleasing. Additionally, a smoother surface allows for better paint adhesion, which is particularly important for those looking to customize or enhance their prints with color and detail.

Sanding 3D Prints The Key to a Smooth Finish

Safety is a crucial aspect of sanding 3D prints as well. The sanding process can produce fine dust, which may harm your respiratory system if inhaled. Therefore, it’s advisable to wear a mask and work in a well-ventilated area. Additionally, working with a dust collector or using a vacuum while sanding can help to keep the workspace clean and minimize dust exposure.

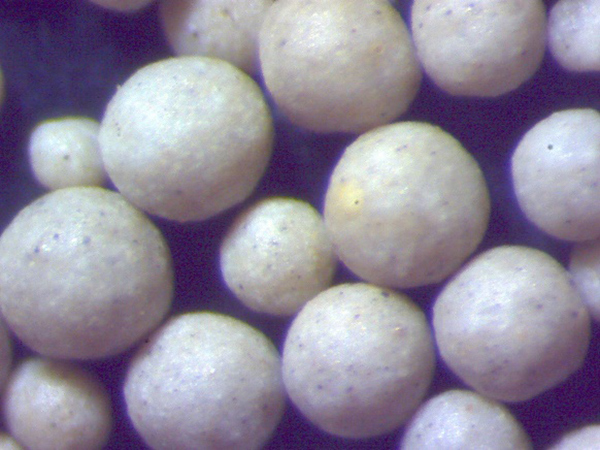

sanding 3d prints

Timing is also an essential factor. Depending on the size and complexity of the print, sanding can be a time-consuming task. It’s important to take a patient approach, allowing yourself ample time to achieve the desired finish. Rushing through the process may lead to uneven surfaces or unintended damage.

Another useful technique involves using wet sanding, which can produce superior results. Wet sanding reduces the amount of dust generated and helps to keep the sandpaper from clogging up, allowing for a more efficient sanding process. It also minimizes the risk of damaging delicate features of the print.

Finally, post-sanding treatments can further enhance the finish of 3D prints. Options include applying a primer before painting, which helps to fill in small gaps and imperfections, or using a plastic filler to smooth out particularly rough areas. For those looking to achieve a glass-like finish, resin coatings can provide an impressive sheen.

In conclusion, sanding is a vital step in the process of finishing 3D prints. By taking the time to smoothen the surface, you can elevate your prints from basic to outstanding. With the right materials and techniques, and a bit of patience, your 3D creations can achieve the polished look you desire, making them suitable for display, sale, or personal use. Happy sanding!

Post time:መስከ . 16, 2024 04:51

Next:High-Quality Resin Coated Sand Manufacturer | Reliable Foundry Solutions