Understanding How Sand Casting Works

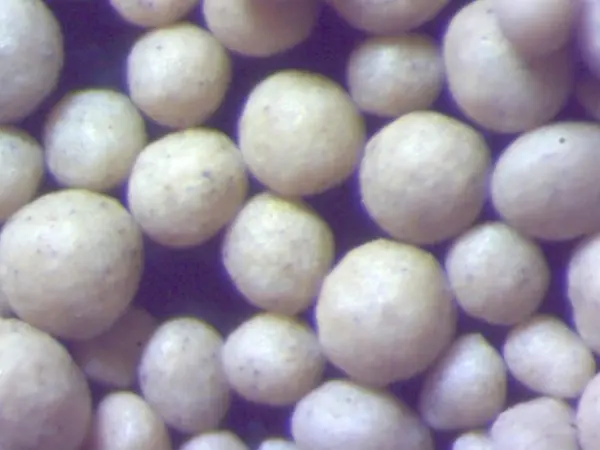

Sand casting is a versatile and widely used manufacturing process for producing metal components. This method continues to be favored due to its simplicity, cost-effectiveness, and ability to create complex shapes. The process involves several key steps that transform raw materials into finished products.

Understanding How Sand Casting Works

Once the mold is created, the pattern is removed, leaving a cavity that mirrors the desired object. This step is critical as the dimensions of the cavity reflect the characteristics of the final product. There are different ways to construct the mold, including green sand casting and resin-bonded sand casting, each offering unique advantages depending on the specific requirements of the part being produced.

how does sand casting work

After the mold is prepared, the next phase involves melting the metal. Common metals used in sand casting include aluminum, iron, bronze, and brass. The metal is melted in a furnace and then poured carefully into the mold cavity. It’s crucial to control the temperature and pouring speed to avoid defects such as porosity or inclusions in the final casting.

Once the metal has cooled and solidified, the mold is broken apart to release the casting. This is often the most satisfying part of the process, as it reveals the finished piece. Afterward, the casting may require cleaning, which involves removing any sand residues and excess material. Techniques like sandblasting and grinding can be utilized to achieve a smooth surface finish.

Finally, the casted components are inspected for quality and dimensional accuracy. Depending on the application, further processing such as machining or heat treatment may be necessary to meet specific tolerances or improve mechanical properties.

In summary, sand casting is a straightforward yet effective method for manufacturing complex components. Its adaptability and efficiency make it a popular choice across various industries, ranging from automotive to aerospace. By understanding the fundamentals of sand casting, manufacturers can leverage this technique to create high-quality parts with precise specifications.

Post time:መስከ . 25, 2024 10:44

Next:Cost Analysis of Sand Casting Processes in Manufacturing Environments