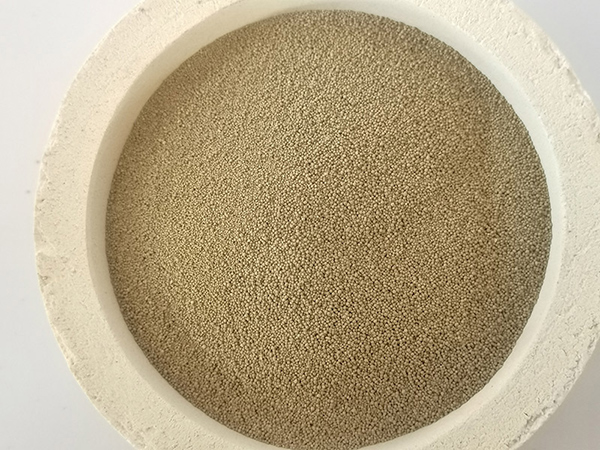

Examples of Sand Casting Products

Sand casting, also known as sand molded casting, is one of the most widely used manufacturing processes in the metalworking industry. It involves the creation of metal parts by pouring molten metal into a mold made from sand. This process is favored for its versatility and cost-effectiveness, making it an ideal choice for producing a vast range of products. In this article, we will explore several examples of products that are created using sand casting.

One of the most common applications of sand casting is in the automotive industry. Many components such as engine blocks, cylinder heads, and transmission cases are produced through this method. For instance, the complex shapes of engine blocks require a robust manufacturing process that can handle intricate designs and precise specifications. Sand casting allows manufacturers to create these components efficiently while ensuring the quality and strength needed for performance under high stress.

Examples of Sand Casting Products

In addition to the automotive and aerospace sectors, machinery and equipment manufacturing benefits from sand casting. Many industrial machines have parts like gear housings, pump casings, and major structural components that are often sand casted. This method allows engineers to produce complex geometries that would be challenging or impossible to achieve with other casting methods. As a result, sand-cast components provide durability and reliability in demanding industrial environments.

examples of sand casting products

Moreover, decorative items and art pieces are also commonly made through sand casting. Artists and designers value this technique for its versatility and the unique surface textures it can produce. Statues, plaques, and intricate sculptures are often created with cast metal, allowing for a beautiful finish and artistic expression. The process not only provides aesthetic appeal but also the strength and longevity required for such items to withstand the elements.

Additionally, sand casting plays a crucial role in producing various household items and tools. Products such as cookware (like cast iron pans), kitchen gadgets, and home decor items benefit from the durability and heat resistance of sand-cast metals. These items are not only functional but also add character to everyday life, showcasing the aesthetic potential of metalwork.

Finally, the construction industry utilizes sand casting for producing components such as brackets, fittings, and valve bodies. These items are essential for infrastructure projects, delivering reliability and strength crucial for safety and functionality in construction applications.

In conclusion, sand casting is a versatile and widely used manufacturing process that contributes to numerous industries, ranging from automotive and aerospace to art and construction. By allowing for the creation of complex shapes and durable materials, sand casting plays a vital role in the production of many everyday products. Its ability to combine quality, cost-effectiveness, and versatility makes it an invaluable method in modern manufacturing. As technology advances, sand casting will continue to evolve, further enhancing its applications and expanding its reach across various fields.

Post time:સપ્ટેમ્બર . 07, 2024 20:36

Next:The History of Sand Casting