Finding Quality Foundry Sand for Sale

When it comes to metal casting, one of the most important materials is foundry sand. This type of sand is crucial for creating molds and cores that hold molten metal during the casting process. The properties of foundry sand, such as its permeability, grain shape, and moisture content, play a pivotal role in the quality of the final product. For those involved in metalworking, understanding where to find quality foundry sand for sale is essential.

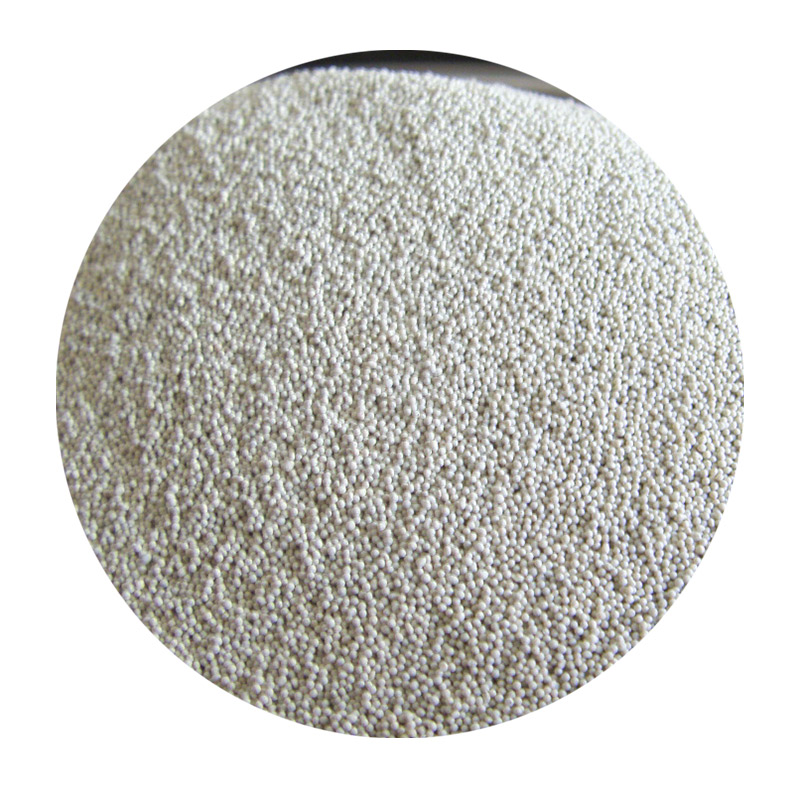

Foundry sand is typically made from high-purity silica, which makes it ideal for casting processes. This sand is created through a rigorous preparation process that includes crushing, washing, and drying to remove impurities and achieve the desired grain size. There are several types of foundry sand available, including silica sand, olivine sand, and zircon sand, each with its unique properties and applications.

Why Foundry Sand Matters

The quality of the sand used in metal casting can significantly influence the performance of the final product. For example, silica sand is widely used due to its excellent thermal properties and ability to withstand the high temperatures of molten metal. It also provides sufficient permeability, allowing gases to escape during the casting process, which helps prevent defects such as burn-on and gas holes. Meanwhile, olivine sand is less common but offers advantages such as better dimensional stability and lower thermal expansion properties.

For anyone involved in the foundry industry, sourcing high-quality foundry sand is vital. Suppliers often provide specifications for their products, allowing manufacturers to choose the right type of sand for their specific casting requirements. As the demand for high-quality castings increases, finding reliable suppliers becomes even more critical.

Searching for Foundry Sand for Sale

foundry sand for sale

When searching for foundry sand for sale, it's important to consider several factors to ensure you are getting the best product for your needs. First, examine the source of the sand. Reputable suppliers often have stringent quality control measures in place to ensure their sand meets industry standards. Look for suppliers who provide certifications and test results that demonstrate their material's quality and compliance with relevant regulations.

Additionally, consider the location of the supplier. Local sources can help reduce shipping costs and ensure timely delivery. Checking if the supplier has a history of serving clients in the metalworking industry can also help establish their credibility.

Another crucial aspect is the price. While it can be tempting to choose the cheapest option available, remember that quality is paramount in the foundry industry. A lower price may indicate inferior quality sand, which could lead to casting defects and increased production costs in the long run. It's often worth paying a bit more for high-quality foundry sand that will yield better results.

Evaluating Suppliers

When evaluating suppliers, don't hesitate to ask for samples. Testing the sand's performance in your casting processes can provide insights into how it will work with your specific metals and methods. Some suppliers may also offer technical support, helping you determine the right sand for your applications.

Online platforms can be invaluable in your search for foundry sand for sale. Many suppliers maintain websites that allow you to compare different products, check availability, and read customer reviews. Don’t overlook online forums and industry groups where professionals discuss their experiences with various suppliers.

In summary, finding quality foundry sand for sale is a crucial task for anyone involved in metal casting. By focusing on reputable suppliers, comparing specifications, considering costs, and evaluating performance, you can ensure you select the right sand for your needs. Whether you are a small workshop or a large foundry, investing in the right materials will ultimately lead to higher quality castings and a more efficient production process. As you embark on your search, remember that the quality of foundation materials, such as foundry sand, plays an essential role in the success of your casting endeavors.

Post time:Dez . 11, 2024 01:57

Next:Creating Stunning Sand Art with 3D Techniques and Tools for Amazing Visual Effects